Microbial biomass conversion processes take advantage of the ability of microorganisms to consume and digest biomass and release hydrogen. Depending on the pathway, this research could result in commercial-scale systems in the mid- to long-term timeframe.

How Does it Work?

In fermentation-based systems, microorganisms, such as bacteria, break down organic matter to produce hydrogen. The organic matter can be refined sugars, raw biomass sources such as corn stover, and even wastewater. Because no light is required, these methods are sometimes called "dark fermentation" methods.

In direct hydrogen fermentation, the microbes produce the hydrogen themselves. These microbes can break down complex molecules through many different pathways, and the byproducts of some of the pathways can be combined by enzymes to produce hydrogen. Researchers are studying how to make fermentation systems produce hydrogen faster (improving the rate) and produce more hydrogen from the same amount of organic matter (increasing the yield).

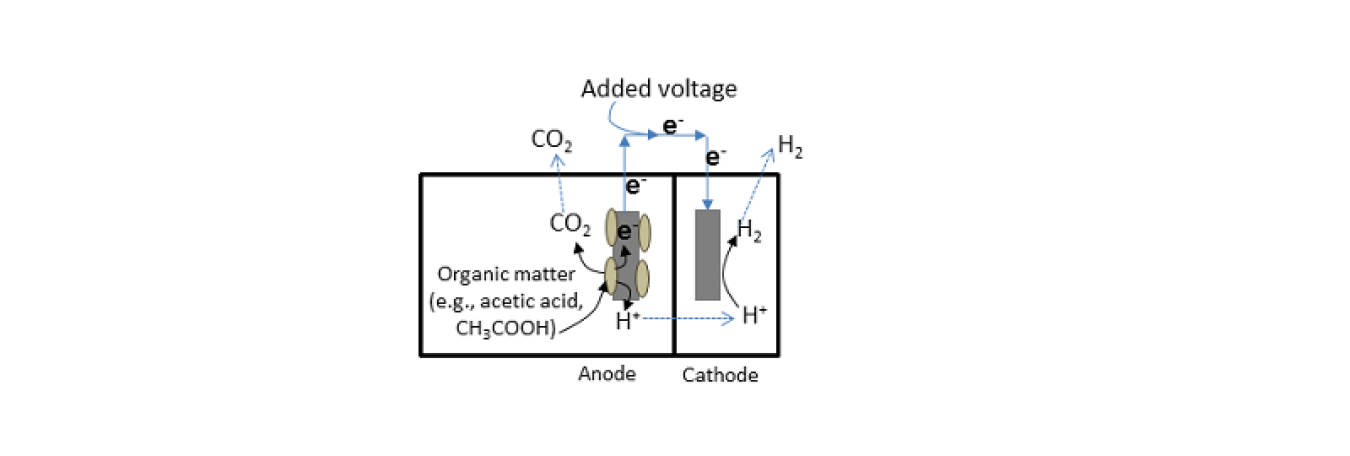

Microbial electrolysis cells (MECs) are devices that harness the energy and protons produced by microbes breaking down organic matter, combined with an additional small electric current, to produce hydrogen. This technology is very new, and researchers are working on improving many aspects of the system, from finding lower-cost materials to identifying the most effective type of microbes to use.

Why Is This Pathway Being Considered?

Biomass is an abundant domestic resource, and many microbes have evolved to efficiently break down biomass to produce hydrogen and other products. Fermentation has already been used as an industrial technology to generate biofuels and other products, and many of the challenges to scaling up systems have been addressed for different products, allowing hydrogen researchers to focus on the challenges unique to hydrogen production. MEC-based systems have the potential to produce hydrogen from resources that otherwise can’t be used for fuel production, and could reduce the large amount of energy normally needed for wastewater treatment while producing a valuable fuel in the form of hydrogen. These two pathways can be combined to maximize the hydrogen yield from the starting biomass feedstock.

Research Focuses on Overcoming Challenges

Research in microbial biomass conversion for hydrogen production has progressed in recent years, but U.S. Department of Energy efforts are working to address a number of challenges. Key areas of research and development include:

- Improving the rates and yields of hydrogen production from fermentation processes through a number of methods such as microbial strain improvements, reactor system optimization, and identifying feedstock sources and processing methods with the highest yields.

- Developing MEC systems that can be scaled up to commercially relevant sizes while maintaining the production rates and system efficiencies seen at the bench scale and minimizing the costs of the reactor components.