Building America research projects are led by teams of building science experts in partnership with leading industry players, such as builders, contractors, and manufacturers, to develop and validate technical solutions that improve the performance of homes while significantly cutting energy use. Learn about how Building America research addresses industry needs by advancing energy-efficient building technologies and practices in three key technology areas:

- High-Performance, Moisture-Managed Envelope Solutions: Technologies and assemblies that increase insulation, reduce infiltration, reduce risk of condensation and mold, and provide adequate drying potential year-round.

- Optimized Low-Load Comfort Solutions: Heating, ventilating, and air-conditioning (HVAC) system solutions to provide highly efficient installed performance and well-distributed airflow, as well as effectively mitigate humidity and comfort risks because of the lower thermal loads in high-performance homes.

- Optimal Ventilation and Indoor Air Quality Solutions: Smart ventilation systems, filtration technologies, and source control for improved indoor air quality in tight homes with little or no energy penalty.

High-Performance, Moisture Managed Envelope Solutions

Optimized Low-Load Comfort Solutions

Optimal Ventilation and Indoor Air Quality Solutions

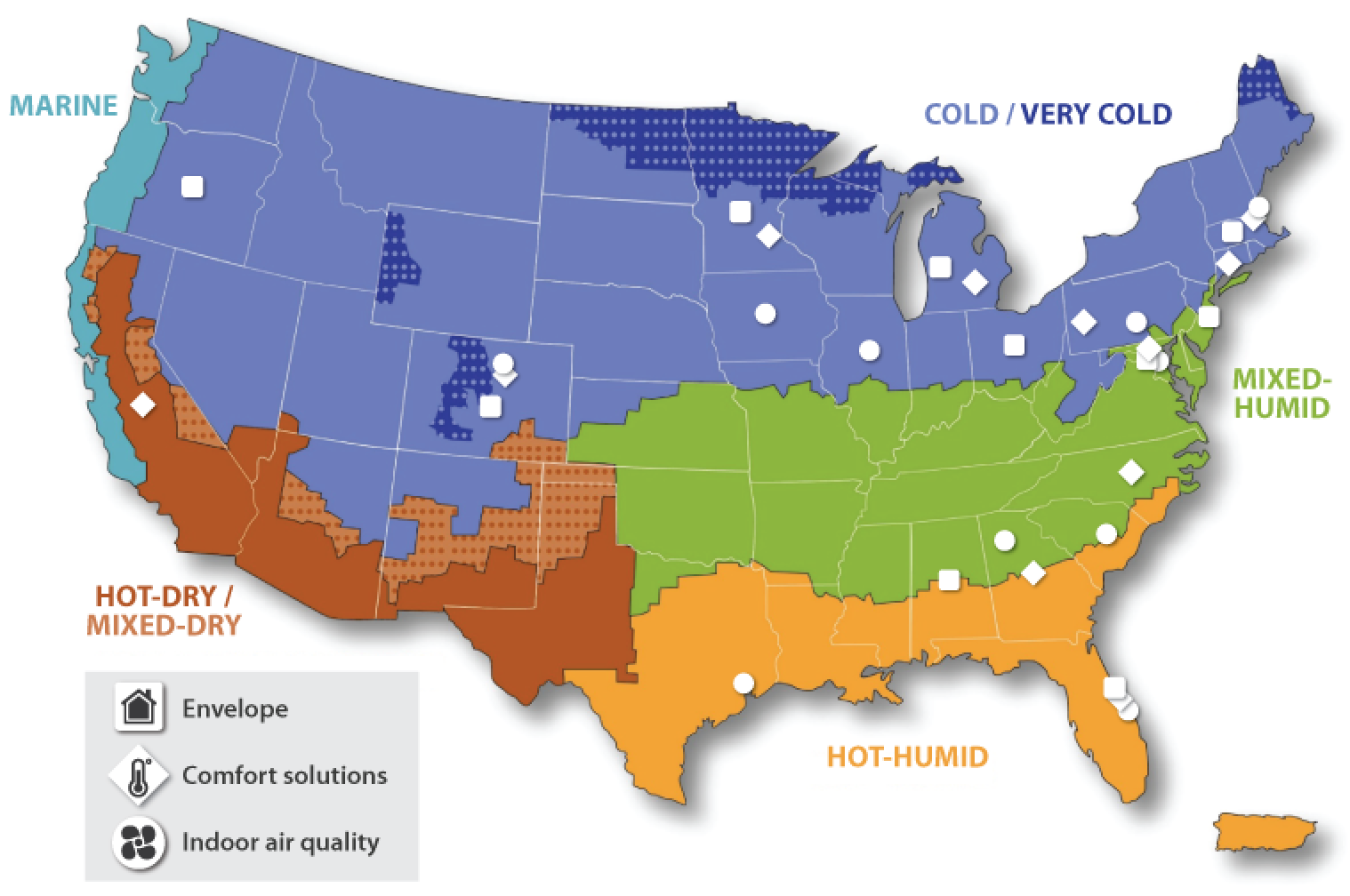

Building America projects are diverse and focus on three key areas.

National Laboratories

DOE's national laboratories are central to Building America research, conducting extensive scientific studies and lending their technical expertise for building technologies and improved building practices. Learn more on our national laboratories web page.

Successes

Over the past 25 years, Building America has supported projects that produced guidance, best practices, and high-performance, energy-efficient homes. Learn more about some of Building America's recently completed projects and successes.