Team Roster: Austin Renfert, Real Estate and Entrepreneurship; Connor Sawyers, International Business and Marketing; Dustin Wahlquist, Finance and Entrepreneurship; Brigham Starks, Environmental Science; Zezhong Du, Agricultural Economics; Ian Berg, Civil and Environmental Engineering; Wilson Towne, Political Science and Economics; Walker Willis, Electrical Engineering; Joe Snodgrass, Electrical Engineering; Brent Grimm, Computer Engineering; Khan Kassymov, Electrical Engineering; Sebastian Subola, Computer Engineering; Ryan Rodenkirch, Electrical Engineering; Evan Wolfenden, Mechanical Engineering; Alex Lebrun, Mechanical Engineering; Benjamin Kufahl, Mechanical Engineering; Emily Blase, Mechanical Engineering; Evan Bauch, Engineering Mechanics and Astronautics.

Students from the University of Wisconsin-Madison competing in the U.S. Department of Energy Collegiate Wind Competition, known as Team "WiscWind," show their school spirit with the "W" sign. L to R: Ian Berg, Dustin Wahlquist, Mamyrkhan Kassymov, Evan Wolfenden, Walker Willis, Alex Lebrun, Benjamin Kufahl, Wilson Towne, Evan Bauch, Emily Blase, Ryan Rodenkirch, Connor Sawyers, and Austin Renfert. Team members missing from photo: Brent Grimm, Zezhong Du, Joseph Snodgrass, Brigham Starks, and Sebastian Subola.

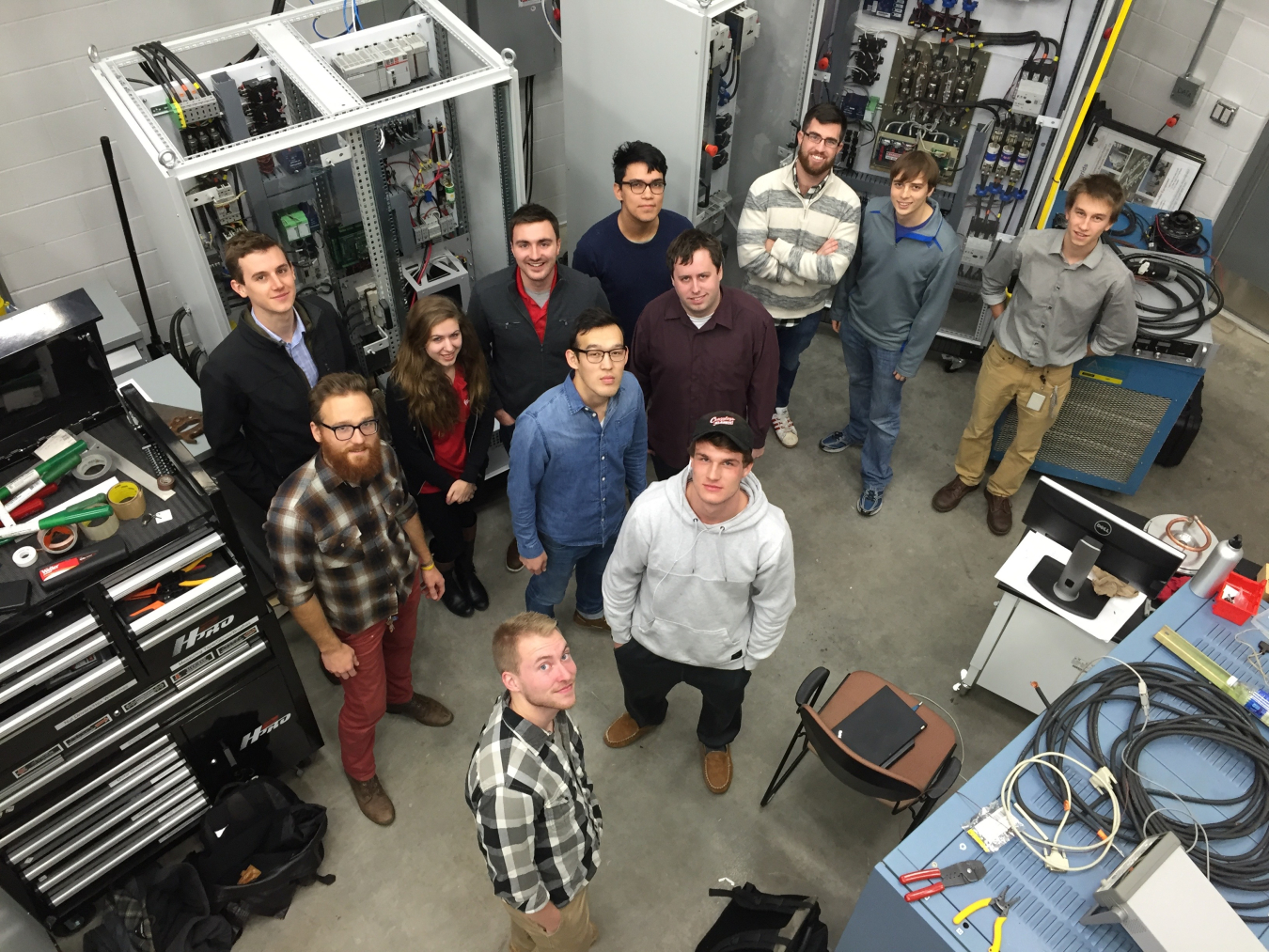

Students from the University of Wisconsin-Madison, known as Team "WiscWind," gather in the Wisconsin Energy Institute's microgrid research lab. Front row (L to R): Ian Berg, Austin Renfert. Middle row (L to R): Walker Willis, Mamyrkhan Kassymov, Ryan Rodenkirch. Back row: Evan Bauch, Emily Blase, Benjamin Kufahl, Sebastian Subola, Joseph Snodgrass, Evan Wolfenden, Alex LeBrun. Team members missing from photo: Connor Sawyers, Wilson Towne, Brent Grimm, Srinidhi Emkay.

Students from the University of Wisconsin-Madison, known as Team "WiscWind," utilize the Wisconsin Energy Institute's open floor plan. Top row (L to R): Evan Wolfenden, Alex Lebrun, Emily Blase, Benjamin Kufahl, Austin Renfert, Dustin Wahlquist, Evan Bauch, Connor Sawyers. Bottom row (L to R): Wilson Towne, Ian Berg, Mamyrkhan Kassymov, Ryan Rodenkirch, and Walker Willis. Team members missing from photo: Brent Grimm, Zezhong Du, Joseph Snodgrass, Brigham Starks, and Sebastian Subola.

TEAM NAME:

WHY WIND?

When asked about the reasons for joining the U.S. Department of Energy Collegiate Wind Competition 2016, students expressed a common interest in renewable energy. Those engaged with the engineering side of the competition expressed an interest in the design process, as well as the opportunity to build something and gain hands‐on experience to complement academic coursework. Those involved with the business and market research component expressed interest in entrepreneurship, particularly in the renewable energy field. In both cases, students want to gain valuable experience with renewable energy and the wind industry and diversify their résumés.

PROJECT DESCRIPTION:

After significant research and coordination with University of Wisconsin–Madison faculty, WiscWind will be pursuing a helical blade vertical axis wind turbine that utilizes a three-phase permanent magnet synchronous machine for electricity generation. A vertical axis wind turbine was chosen to reduce the number of mechanical/moving components (blade pitching and gear reduction). This will lead to a more robust and maintenance-free design and a more marketable product.

Currently, the turbine is being designed for a battery that will be capable of powering electrical loads for several markets throughout India. India was chosen as an ideal market for off-grid wind because parts of India experience some of the strongest global wind resources and 21.3% of India’s population is without access to electricity, according to a 2012 study compiled by The World Bank.

Off‐grid wind turbines would be an effective electric solution for three major markets:

- Health clinics (lights, vaccine refrigerators, and health-care machines)

- Rural village homes (lights, electric stoves, and heat)

- Cellular towers (corresponding with a push for more widespread cell-phone availability).

Further research is being conducted by the business subteam related to each of these markets, including marketable and deployable loads specific to each. In the health clinic and rural village market, an important load would be a reliable and safe lighting system, so consideration is being given to designing for this product.

It is also important to note that the team spent substantial time and resources pursuing a different market completely, aiming to power sensors and other electronic equipment associated with precision agriculture. However, research and communication with potential customers led to the decision to move the team in this new direction.

GAME PLAN:

WiscWind’s business strategy consists of defining a problem, creating hypotheses, and testing them. The key hypothesis is that the team will be able to create a prototype turbine that will scale up to be the best solution to the problem. To prove that this hypothesis is valid, several students enrolled in a venture creation class to better understand how to define a market and target customers. The goal is not only to prove that an off-grid wind turbine will solve a specific problem, but also that an off‐grid wind turbine will be a more cost‐effective option than drawing current from an existing power grid (using data gathered by the deployment team). The team also aims to prove that an off‐grid wind turbine will be more cost-effective than any other off‐grid energy source, renewable or otherwise.

From there, the business subteam works with the electrical and mechanical subteam to create a turbine that will provide unique value, using Lean principles to ensure that every component of the design provides value to the end customer. To test all these hypotheses, the business team is in the process of interviewing researchers, industry professionals, and potential customer contacts. Information from the customers is added to a business model canvas in real time and continually updated to the needs of the customers, with the end goal of creating a business plan that proves the turbine is the ideal solution to the problem.

The technical strategy of the team is to use an iterative process for turbine development. The team will utilize local 3-D printing resources (including the University of Wisconsin–Madison Polymer Engineering Center and two local manufacturers) to print the helical blade structure with polycarbonate, Acrylonitrile-Butadiene-Styrene, Nylon 12 plastic, or similar material. These blades will be attached to a common vertical axis wind turbine frame (made of machined aluminum or printed plastic) via a series of fasteners. This strategy allows the team to use the following iterative design method:

- Design airfoil and blade structure

- Mount blades to common vertical axis wind turbine frame

- Test turbine in wind tunnel (property of University of Wisconsin–Madison Department of Engineering Physics) and record results

- Analyze results and repeat.

Because of the difficulty in modeling a vertical axis wind turbine, the team has decided that this is the best strategy for developing a rigorous turbine design. An additional benefit to this strategy is the ability to effectively replace components should a malfunction or failure occur. When an optimal combination of airfoil type, blade twist, and frame structure has been achieved, it will be thoroughly tested and documented in the technical section of the final report.

TEAM STRENGTH:

Business Plan

WiscWind has a resourceful and dedicated business subteam that has been committed to finding a healthy target market. The team is receiving additional help from students in a Venture Creation course through the Wisconsin School of Business. Two of these students (Austin Renfert and Evan Wolfenden) are full members of the team and will continue their efforts into the spring semester.

Technical Design

The WiscWind electrical subteam is remarkably talented, featuring experienced students from both electrical and computer engineering disciplines. The subteam has been in direct contact with an electrical and computer engineering professor with extensive experience with electric machines and power electronics. Much of the turbine is controlled via electronics, making the mechanical design less complex in terms of assembly because a gearbox and active blade pitch control can be avoided.

Deployment Strategy

The team has been in contact with a professor in geological engineering with substantial knowledge of the wind industry and associated deployment concerns. The team also has resources in the Office of International Programs, including a global health course taught by a professor in that department.

Turbine Performance Testing

The absence of mechanical systems to control blade pitch and gear reduction results in fewer moving components prone to failure. With access to a wind tunnel owned by the Department of Engineering Physics, the design can be tested and retested until an ideal solution is achieved.

Bonus Challenge

The main advantage of a vertical axis wind turbine is its ability to produce power in multidirectional wind. As the competition testing will occur in a tunnel with a one‐directional airstream, this benefit is attenuated.

One possibility for the wind-driven load is a lighting system. This gives WiscWind several interesting and visually appealing ways to illustrate the power production of a wind turbine using lights.

TEAM HURDLES:

Business Plan

The challenges associated with the business plan aspect of the competition are governed by identifying a strong target market for the turbine and load. It has been challenging thus far in finding a market niche that is competitive with solar solutions, particularly for off‐grid applications.

Technical Design

The unique geometry of the helical blade structure in a vertical axis wind turbine presents manufacturing challenges that the team will need to address. Several manufacturing processes are being considered. Additionally, a vertical axis wind turbine is controlled largely via power electronics because of blade pitch control difficulty. A robust electronics system is necessary for safe and reliable function of the turbine and load.

Deployment Strategy

One of WiscWind’s target markets may be developing countries that lack reliable electricity access. There are challenges with the process of distributing a wind product to an international customer, particularly one in developing parts of the world.

Turbine Performance Testing

The main advantage of a vertical axis wind turbine is its ability to produce power in multidirectional wind. As the competition testing will occur in a tunnel with a one‐directional airstream, this benefit is attenuated. Because the entire chassis of the vertical axis wind turbine will be spinning during operation, it will be more difficult to balance and address vibration.

Bonus Challenge

Because the entire chassis of the vertical axis wind turbine will be spinning during operation, it will be more difficult to balance and address vibration. Also, because the team’s turbine is not yet targeted at a specific electrical load, there are challenges ahead with determining a useful and marketable wind-driven load and displaying that load in an attractive and creative manner. Moving forward, it will be important to dedicate as much time to manufacturing the load as building a robust turbine.

TEAM TAKEAWAYS:

For WiscWind, the most important aspect of the Collegiate Wind Competition 2016 is the learning experience that comes with guiding a product through the design process. The competition provides each of the team members with valuable experience in working within a multifaceted team pursuing a common goal. The cross‐functionality between business, mechanical, and electrical subteams thus far has been crucial to the design process and continues to drive WiscWind in each of its decisions. The competition continues to show the team the importance of designing a product with the customer and market in mind—not only creating an elegantly engineered solution, but also one that satisfies a market niche.

Furthermore, the competition has given the members of WiscWind the opportunity to learn from some of the most talented professors and wind experts at the University of Wisconsin–Madison. The classroom time spent with these professors has been enlightening, and the ability to consult them throughout the design process is proving instrumental to the team’s success.

Looking beyond the 2016 competition, the potential to establish long‐term relationships between the wind industry and University of Wisconsin–Madison for opportunities such as internships, university recruiting, and industry‐sponsored research could be greatly beneficial.