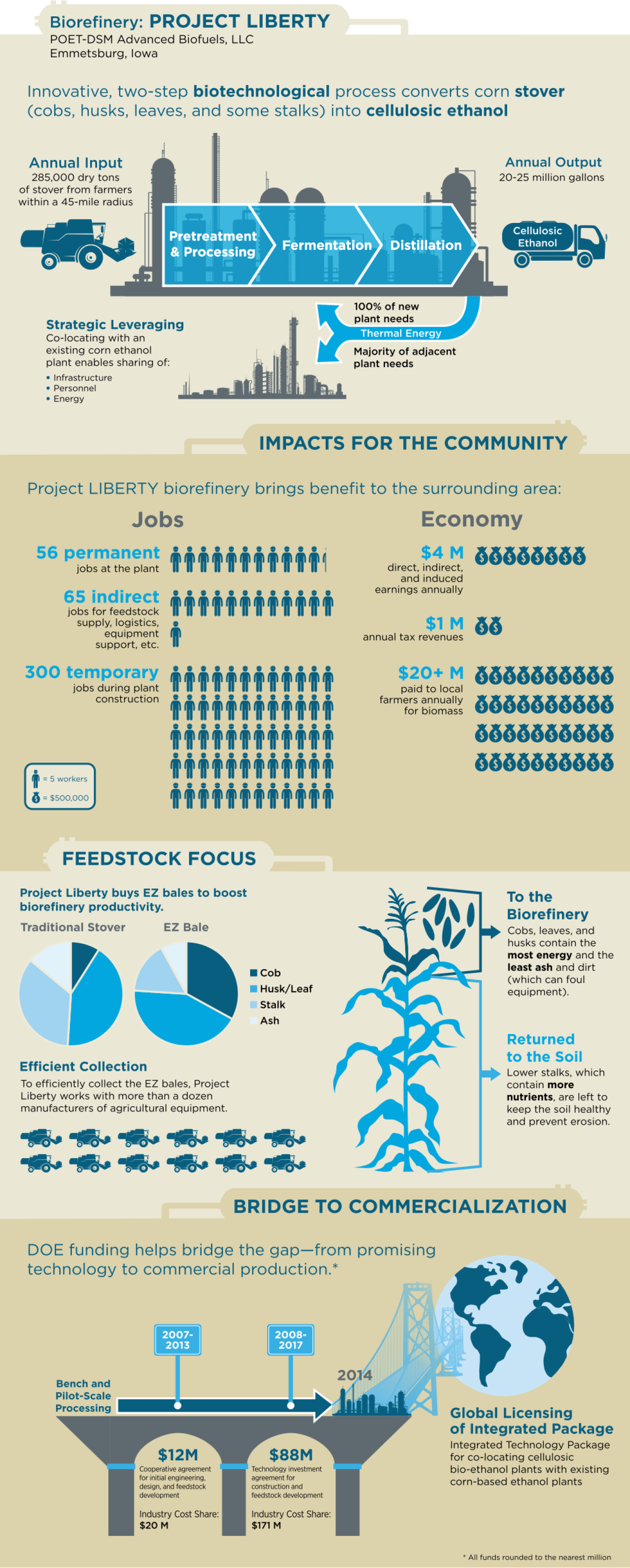

Project LIBERTY, POET-DSM’s new biorefinery in Emmetsburg, Iowa, began producing cellulosic ethanol from corn stover on September 3, 2014. This state-of-the-art facility uses a biological process to convert post-harvest corn stover (cobs, leaves, husks, and upper stalks) into a biofuel that will help build U.S. fuel independence, reduce climate impacts, and create new jobs. The facility could increase Iowa’s economic output by $24.4 billion and create more than 13,500 jobs in the state over the next 20 years.[1]

The U.S. Department of Energy contributed $100 million in cost-shared support for the development, design, and construction of this pioneer facility, which has the capacity to produce up to 25 million gallons of cellulosic ethanol annually. It is one of the first generation of large-scale U.S. biorefineries to produce biofuel from agricultural waste. With the successful scale up this novel technology, the biorefinery will help to advance U.S. competitiveness in energy technology while providing American farmers with an additional revenue stream.

The biorefinery is designed to ensure the viability of its feedstocks, processes, and products. For example, after working with government agencies and universities to clarify the impacts of corn stover removal on soil health, POET-DSM developed its innovative EZ Bale system. By leaving approximately 75% of the biomass in the field and focusing on the collection of cobs, leaves, and husks, this system protects against erosion and leaves the bulk of the nutrient-rich lower stalks to replenish the soil. The corn stover that is included in EZ Bales provides a higher energy content feed and less ash to foul equipment in the biorefinery. In effect, corn stover components are assigned to their best use—whether it’s sustaining soil health or stimulating the rural economy.

To make it easier for farmers in the surrounding area to collect EZ Bales, POET-DSM has worked with more than a dozen manufacturers of harvest equipment, which include AGCO, Case IH, Claas, Demco, Fantini, John Deere, Ken's Truck & Trailer, Milstak, Redekop, Stinger, SmithCo, Unverferth, Vermeer, and Wildcat. Local farmers are now under contract to deliver the EZ Bales, which also help them manage their crop residue and decrease tillage.

Once the collected corn stover arrives at Project LIBERTY, it is weighed, documented, and stored in the stack yard or brought directly to the Biomass Building for immediate processing. The corn stover begins processing by undergoing a series of physical and passive pretreatment processes that start to break down its rigid cell walls so that the basic sugar components can be extracted and fermented. The resulting product is then distilled into 200-proof ethanol, denatured, and shipped to refiners for blending with gasoline. The portion of the corn stover (primarily lignin) that cannot be converted to biofuel is used to generate the thermal power needed by Project LIBERTY—and much of that power required by the adjacent corn ethanol plant.

Project LIBERTY was strategically situated right next to POET’s existing first-generation corn ethanol plant in Emmetsburg to share energy, land, rail spurs/roadways, storage, feedstock supply network, and personnel. Once this novel production technology is fine-tuned, POET intends to adopt it in at the other 27 corn ethanol plants it operates in North America. The integrated technology package is also being licensed for use around the globe.