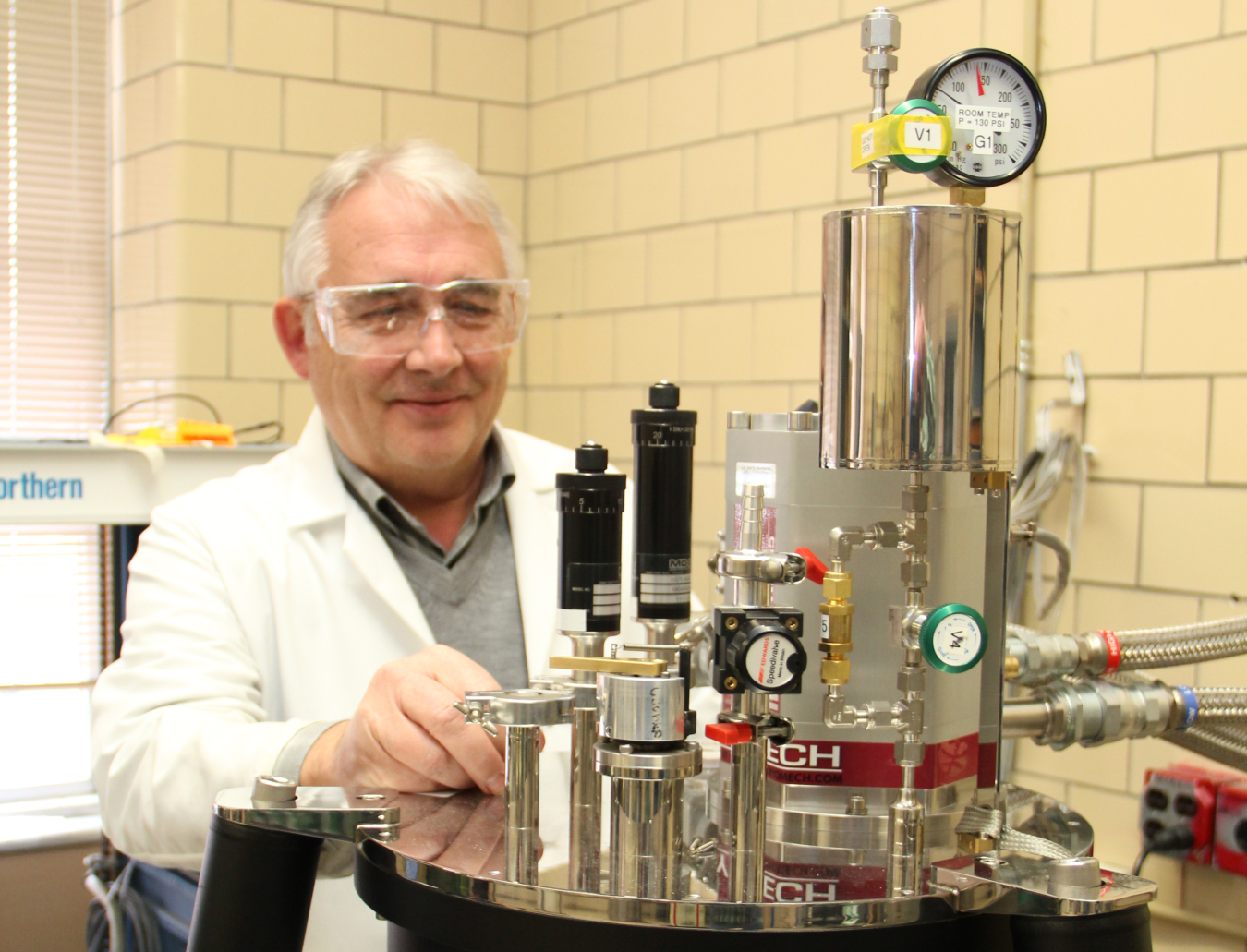

Dr. Vitalij Pecharsky in his research facility at Ames Laboratory, working with a calorimeter. <em>Photo courtesy of Ames Laboratory. </em>

At least one out of every five kilowatt-hours of energy in the U.S. is used by cooling systems. Cooling technologies are a vital part of everyday life for Americans including food storage, cryostorage in medical applications, and simple matters of comfort like air conditioning. The current materials being used in vapor-compression refrigeration are not ideal long term solutions. Environmental regulations are phasing out hydrofluorocarbons with high global warming potential used in vapor compressors. The current vapor-compression technologies are already approaching their efficiency limits. Advances in new energy conversion materials and technologies can create more environmentally friendly processes and increased efficiency, with the potential to reduce the amount of energy required for cooling by 20 to 30%.

On February 24, 2016, the U.S. Department of Energy (DOE) announced the launch of its Energy Materials Network (EMN), a new National Laboratory-led initiative that will give American entrepreneurs and manufacturers a leg up in the global race for clean energy. Leveraging $40 million in federal funding, EMN will focus on tackling one of the major barriers to widespread commercialization of clean energy technologies: the design, testing, and production of advanced materials. DOE’s Office of Energy Efficiency and Renewable Energy is providing the funding to establish EMN’s four initial National Laboratory-led consortia and solicit proposals for collaborative R&D projects with industry and academia.

Each EMN consortium will bring together National Labs, industry, and academia to focus on specific classes of materials aligned with industry’s most pressing challenges. The Advanced Manufacturing Office (AMO) is proud to sponsor the CaloriCoolTM consortium, led by Ames Laboratory, which will focus on caloric materials and advanced refrigeration technology. CaloriCoolTM’s goal is to provide computationally intensive, materials-driven discovery paired with a high throughput experimental testbed for rapid assessment and characterization of caloric materials combined with systems-level analysis to drive technical impact.

The caloric effect is the process by which a driving force (magnetic, applied stress, or electric) causes a change in temperature in the material. For the caloric materials on which CaloriCoolTM will focus, that temperature differential could be up to 40°C (72°F). Ames Laboratory, which is part of DOE’s network of national laboratories, is an organic fit for CaloriCoolTM because of its enduring foundational capability in caloric materials. The consortium will be led by caloric materials expert Dr. Vitalij Pecharsky of Ames, who co-discovered a material with Dr. Karl Gschneidner that exhibited a giant magnetocaloric effect (a caloric effect created through a magnetic field).

“Following our discovery of the giant magnetocaloric effect, it took everyone almost twenty years to realize that what really holds the technology back from commercialization is the lack of a viable material with a strong enough caloric cooling effect,” said Dr. Pecharsky. “Once we develop the materials that are suitable and cost-effective, the technology can make the leap forward on its own.”

CaloriCoolTM will focus on laying the groundwork and infrastructure for the consortium over the next few months and will fully launch in FY17. Other CaloriCoolTM partners include Pacific Northwest and Oak Ridge National Laboratories, University of Maryland, Pennsylvania State University, United Technologies Research Center, GE Global Research, Astronautics Corporation of America, and Citrine Informatics.

The research done by CaloriCoolTM will accelerate innovation with industry-leading clean energy technologies, positioning the U.S. competitively in the global marketplace with products invented, made, and used right here at home. To learn more about the DOE’s commitment to advanced materials innovations, visit the Energy Materials Network website.