Stay on top of the latest developments in advanced materials and manufacturing technologies. Miss some newsletters? Check out the archive.

The Advanced Materials and Manufacturing Technologies Office (AMMTO) supports a globally dominant U.S. manufacturing and industrial base for a resilient energy system and secure supply chain. Our mission is to drive and inspire innovation that transforms materials, manufacturing, and workforce and advances America’s energy economy. AMMTO supports domestic manufacturing and a strong and resilient energy sector by providing analysis, planning, management, and direction necessary for a balanced program of research, development, demonstration, technical assistance, and advanced manufacturing workforce development.

AMMTO is a suboffice within the U.S. Department of Energy's Office of Energy Efficiency and Renewable Energy.

Learn More

News and Announcements

-

- Unleash American Energy Innovation

- National Labs

- National Labs

- National Labs

- National Labs

- National Labs

- National Labs

- National Labs

February 19, 2026 -

- Priorities

- Funding Opportunities

- Funding Opportunities

- Funding Opportunities

- Funding Opportunities

August 13, 2025

Programs

-

DOE makes strategic investments to advance material supply chains and product lifecycles in support of a robust manufacturing sector and secure supply chain.November 19, 2025

DOE makes strategic investments to advance material supply chains and product lifecycles in support of a robust manufacturing sector and secure supply chain.November 19, 2025 -

DOE pursues novel manufacturing processes and digital systems that enhance materials and energy efficiency to deliver benefits throughout the economy.April 9, 2025

DOE pursues novel manufacturing processes and digital systems that enhance materials and energy efficiency to deliver benefits throughout the economy.April 9, 2025 -

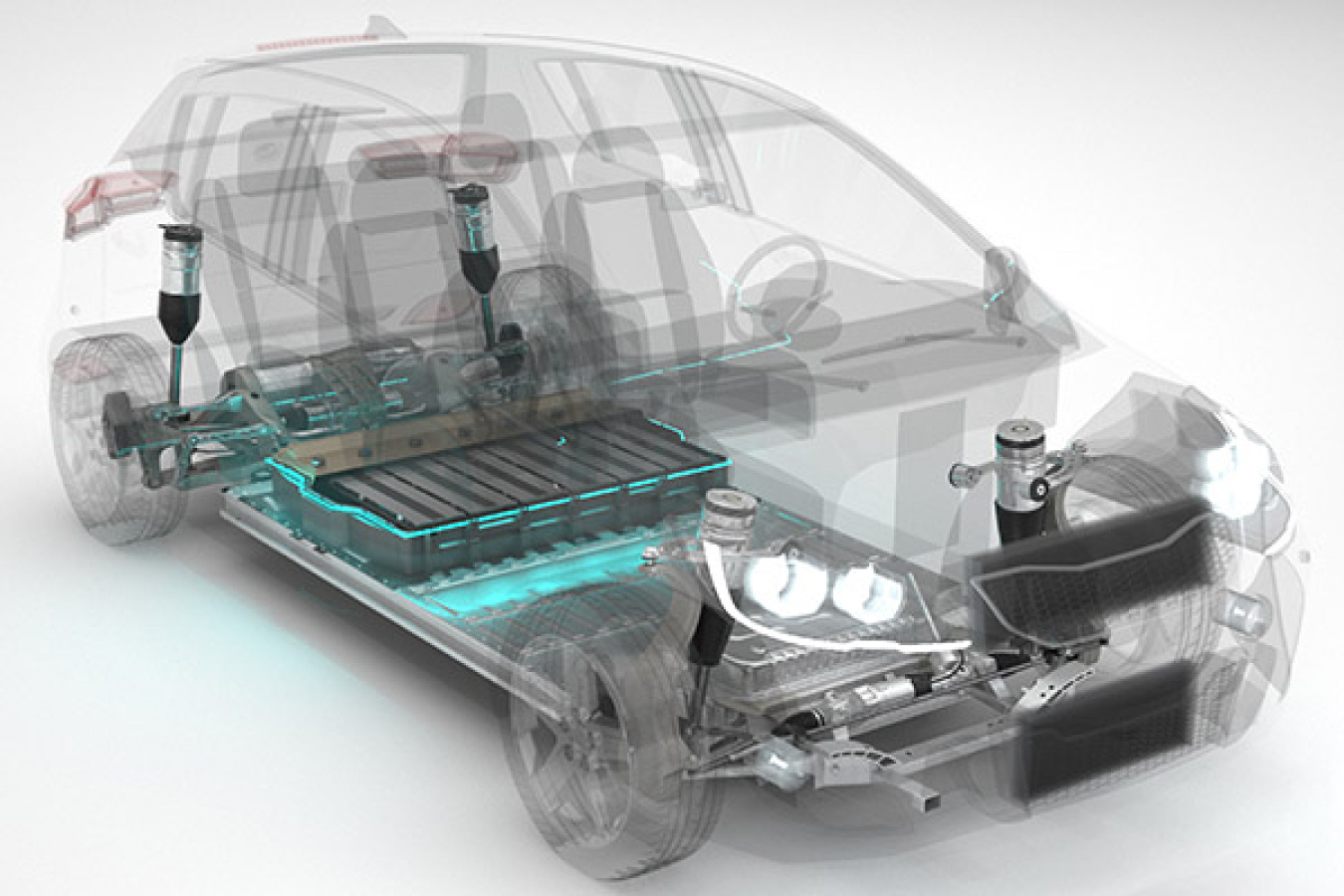

AMMTO advances workforce education and entrepreneurial ecosystems for key energy system-enabling technologies, such as semiconductors and batteries.December 2, 2024

AMMTO advances workforce education and entrepreneurial ecosystems for key energy system-enabling technologies, such as semiconductors and batteries.December 2, 2024

Advanced Materials and Manufacturing Basics Explainers

Learn the basics of advanced materials and manufacturing technologies and processes supported by AMMTO.

The first installment of the Breaking It Down series aims to inform and inspire people by putting next-generation batteries into simpler terms.

Resources

AMMTO Project Map

Learn more about the projects AMMTO is funding and has supported in the past.

Join Our Team

Find Funding

Learn more about AMMTO!

Contact Us

Advanced Materials and Manufacturing Technologies Office

Office of the Assistant Secretary

Energy Efficiency and Renewable Energy

Mail Stop EE-1

Department of Energy

Washington, DC 20585