Metallurgists at the Office of Fossil Energy’s National Energy Technology Laboratory (NETL) have helped develop a new alloy that is increasing the safety of an important medical procedure by being used to manufacture more flexible and conformable cor...

Office of Fossil Energy and Carbon Management

August 2, 2011

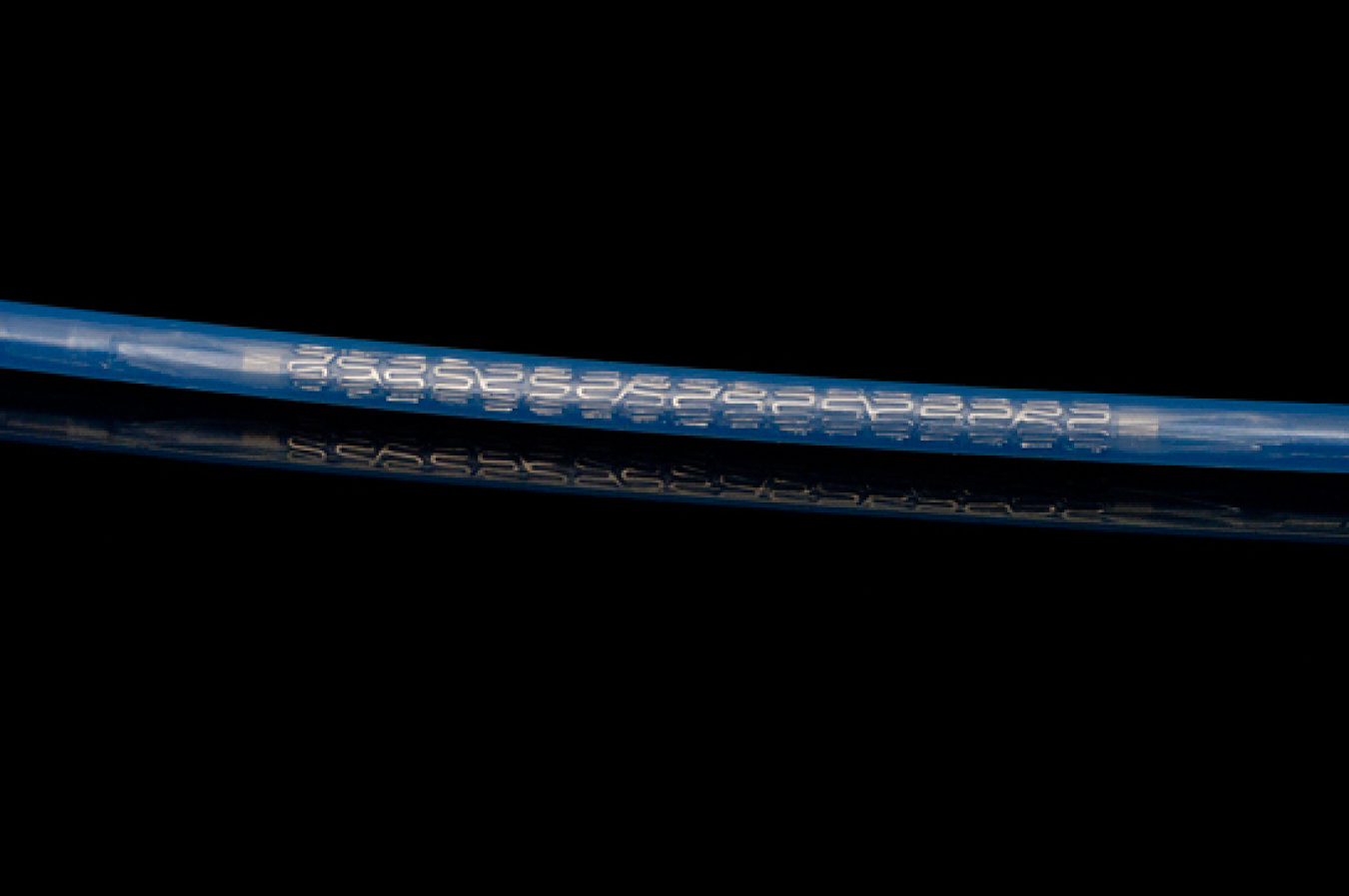

Coronary stents made from a novel PtCr alloy are more flexible and conformable than traditional stents. The PtCr alloy was developed by a research team that included metallurgists from NETL. The improved

stents are manufactured by Boston Scientific Corporation. Photo courtesy of Boston Scientific Corporation.

Washington, DC -- Metallurgists at the Office of Fossil Energy’s National Energy Technology Laboratory (NETL) have helped develop a new alloy that is increasing the safety of an important medical procedure by being used to manufacture more flexible and conformable coronary stents.

Coronary stents made from a novel PtCralloy are more flexible and conformablethan traditional stents. The PtCr alloy wasdeveloped by a research team that includedmetallurgists from NETL. The improvedstents are manufactured by Boston Scientific Corporation. Photo courtesy of Boston Scientific Corporation.The novel platinum-chromium (PtCr) alloy, developed by a research team at NETL and Boston Scientific Corporation (Natick, Mass.), is being used to manufacture coronary stents that allow easier placement by the doctor and more safety for the patient.

A coronary stent is a small, expandable mesh tube that is placed in a narrowed or weakened coronary artery, allowing the passageway to stay open. Every year coronary stents save thousands of lives by expanding diseased arteries and allowing blood to flow freely.

NETL’s involvement in the project goes back more than 10 years, when scientists at Boston Scientific requested the laboratory’s help with research to improve the traditional 316L stainless steel traditionally used in coronary stents. Boston Scientific recognized NETL’s metallurgy capabilities and offered to fund the entire research project. Over the next decade, NETL and Boston Scientific researchers worked together to design the PtCr alloy and develop the process methodology to produce the alloy for use as stent material.

The PtCr alloy solves many of the past problems surrounding traditional stents. The addition of platinum provides physical properties that allow a stent to be both thin and visible on x-ray, a problem with stainless steel stents. Its flexibility allows easier movement through arterial bends without causing damage. The addition of high-melting platinum also gives the stent a higher corrosion resistance, which optimizes the stent’s long-term stability within the body. The alloy’s increased strength also decreases recoil, which reduces the likelihood of constriction after deployment.

Following a series of trials--melting, casting, fabricating, and characterizing the properties of different alloys--and after many clinical trials, Boston Scientific’s PROMUS® ELEMENT and ION stents, made from the novel PtCr alloy, were ready to market. Since introduction of the improved coronary stents in January 2010, sales have exceeded $1 billion. The breakthrough was recognized by R&D Magazine, which named the PtCr alloy one of the 100 most technologically significant products to enter the marketplace in the past year.

NETL’s materials sciences research team has conducted a wide variety of work in high-temperature alloy development and processing. NETL’s materials research includes making more effective armor for the Army, new turbine alloys to help the Nation’s power systems operate more efficiently, and now a medical alloy that helps save lives.

<p>FECommunications@hq.doe.gov</p><p> </p>