Research supported by the Department of Energy's (DOE) National Energy Technology Laboratory (NETL) has led to a discovery that could significantly increase the efficiency of turbines in fossil fuel electricity generation.

Office of Fossil Energy and Carbon Management

April 26, 2016

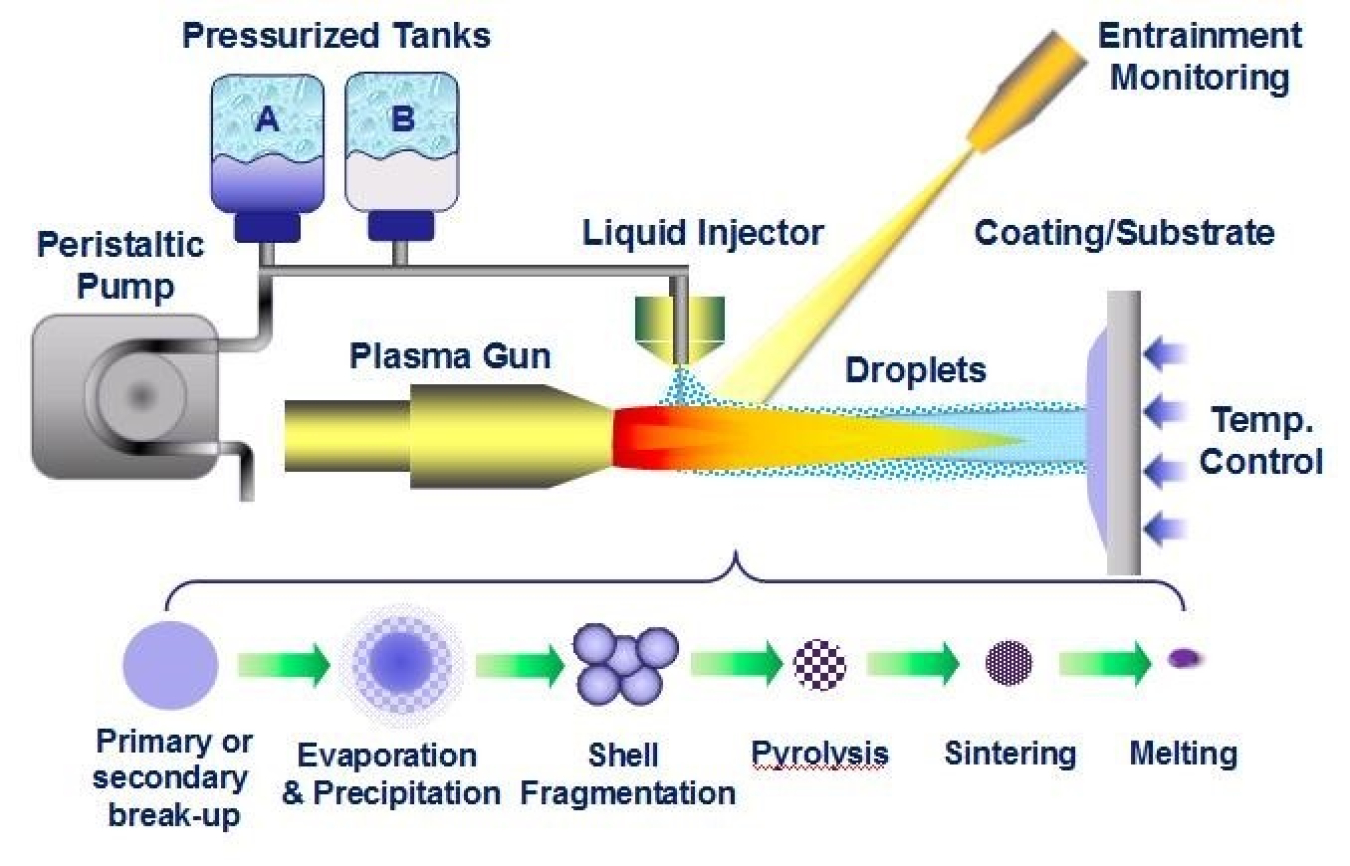

Schematic Diagram of the Breakthrough Thermal Barrier Coating by “Solution Precursor Plasma Spray” Process

Research supported by the Department of Energy's (DOE) National Energy Technology Laboratory (NETL) has led to a discovery that could significantly increase the efficiency of turbines in fossil fuel electricity generation. This breakthrough could reduce carbon dioxide (CO2) emissions from power plants and help drive the clean energy economy in the U.S.

Gas turbines are the main electricity-generating components in most power plants. When they operate at high temperatures, they use less fuel, operate more efficiently, and enable carbon capture technologies to more effectively reduce greenhouse gas emissions.

The problem is that the materials that protect the turbines from high heat – known as thermal barrier coatings – degrade and fail when they’re exposed to temperatures that exceed 1,200°C, which is required for more efficient operations and greenhouse-gas capture.

Now, there may be a solution to this problem.

Working under an NETL-sponsored Small Business Technology Transfer project, researchers from HiFunda LLC and the University of Connecticut successfully demonstrated that an oxide called yttrium aluminum garnet (YAG) deposited by the relatively new process “solution precursor plasma spray” (SPPS) provides a thermal barrier coating with the potential for use at 1,500 °C. That’s a 300 °C temperature advantage compared to current state-of-the-art air plasma-sprayed thermal barrier coatings.

Nine major industrial partners are now testing this technology and evaluating the process in production facilities. In addition, a new spin-off company—Solution Spray Technologies LLC, a Delaware company with operations in Connecticut—has been created to be a thermal barrier coating service provider for this new technology.

If adopted throughout the gas turbine industry, this technology could significantly increase turbine efficiency and reduce overall fuel consumption. It may also enable development of technologies for next-generation, high-temperature, high-efficiency systems that could lay the ground work for more effective carbon capture in power plants – and help to drive the clean energy economy.

DOE’s Small Business Technology Transfer program expands funding opportunities, like this, in the federal innovation arena. The program provides opportunities for small businesses and nonprofit research institutions to collaborate on projects that bridge the gap between performance of basic science and commercialization of resulting innovations. Learn more about NETL’s Small Business Technology Transfer project.