RSS

September 30, 2025 The more than 80 community leaders who took part in the recent Paducah Chamber of Commerce Fly-In discussed environmental cleanup progress, upcoming project milestones and long term planning for reindustrialization of the Paducah Site with members of Kentucky’s congressional delegation and U.S. Department of Energy leaders.

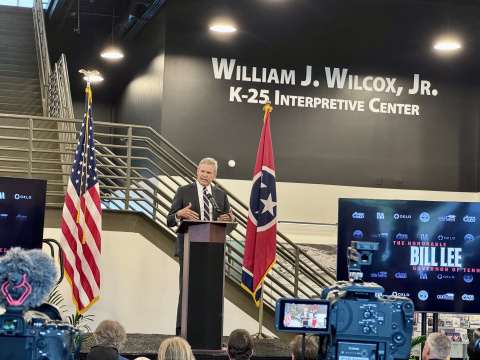

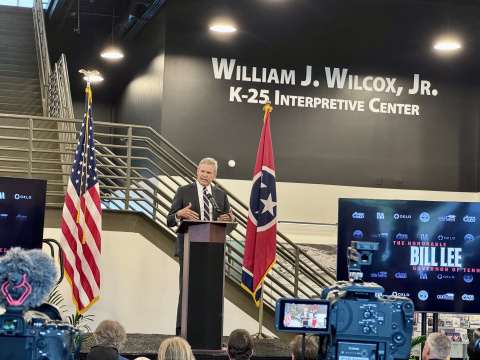

Oklo Inc. recently announced plans to build the first privately funded commercial nuclear fuel recycling facility at Oak Ridge’s East Tennessee Technology Park. September 23, 2025

U.S. Department of Energy officials and Paducah, Kentucky, community members take part in a meeting of the annual Paducah Chamber of Commerce Fly-In. September 23, 2025

Workers at the Hanford Site have removed a facility once used to prepare spent nuclear fuel for storage, marking continued progress in the U.S. Department of Energy Office of Environmental Management’s risk-reduction work near the Columbia River. September 23, 2025

The U.S. Department of Energy Office of Environmental Management has reached another significant milestone with concurrence from regulators that radioactive waste has successfully been removed from another tank at the Savannah River Site. September 23, 2025

An innovative robotic technology has confirmed the integrity of most legacy transuranic waste drums at the Idaho National Laboratory Site screened so far, enabling their safe and compliant shipment to the Waste Isolation Pilot Plant for disposal and saving taxpayers a potential $20 million. September 23, 2025

The U.S. Department of Energy Office of Environmental Management Paducah Site has incorporated amateur radio into a drill for its emergency management program. September 23, 2025

The Oak Ridge Office of Environmental Management has met its goal to complete eight shipments of transuranic waste to the Waste Isolation Pilot Plant for permanent disposal this fiscal year ending Sept. 30, further reducing its inventory of the material. September 23, 2025

U.S. Department of Energy Office of Environmental Management crews recently reached a historic milestone of over 40 million safe hours at the Savannah River Site and received an award from the National Safety Council at the Paducah Site. September 16, 2025

The Hanford Field Office is tackling the legacy of the past, cleaning up decades-old radioactive waste stored in large underground tanks. September 16, 2025