The Vehicle Technologies Office (VTO) supports research and development of aftertreatment technologies to control advanced combustion engine exhaust emissions. All engines that enter the vehicle market must comply with the Environmental Protection Agency's emissions regulations. Harmful pollutants in these emissions include:

Left: Spatially resolved, capillary-inlet mass spectrometer; Right: Spatially resolved, capillary-inlet mass spectrometer.

- Carbon monoxide

- Nitrogen oxides

- Unburned hydrocarbons

- Volatile organic compounds (VOCs)

- Particulate matter

The energy required for emission control often reduces vehicle fuel economy and increases vehicle cost. VTO's Emission Control R&D focuses on developing efficient, durable, low-cost emission control systems that complement new combustion strategies while minimizing efficiency losses. VTO often leverages the national laboratories' unique capabilities and facilities to conduct this research. To enable further developments in these areas, VTO also supports research into materials for controlling exhaust gases and materials by design for exhaust after-treatment.

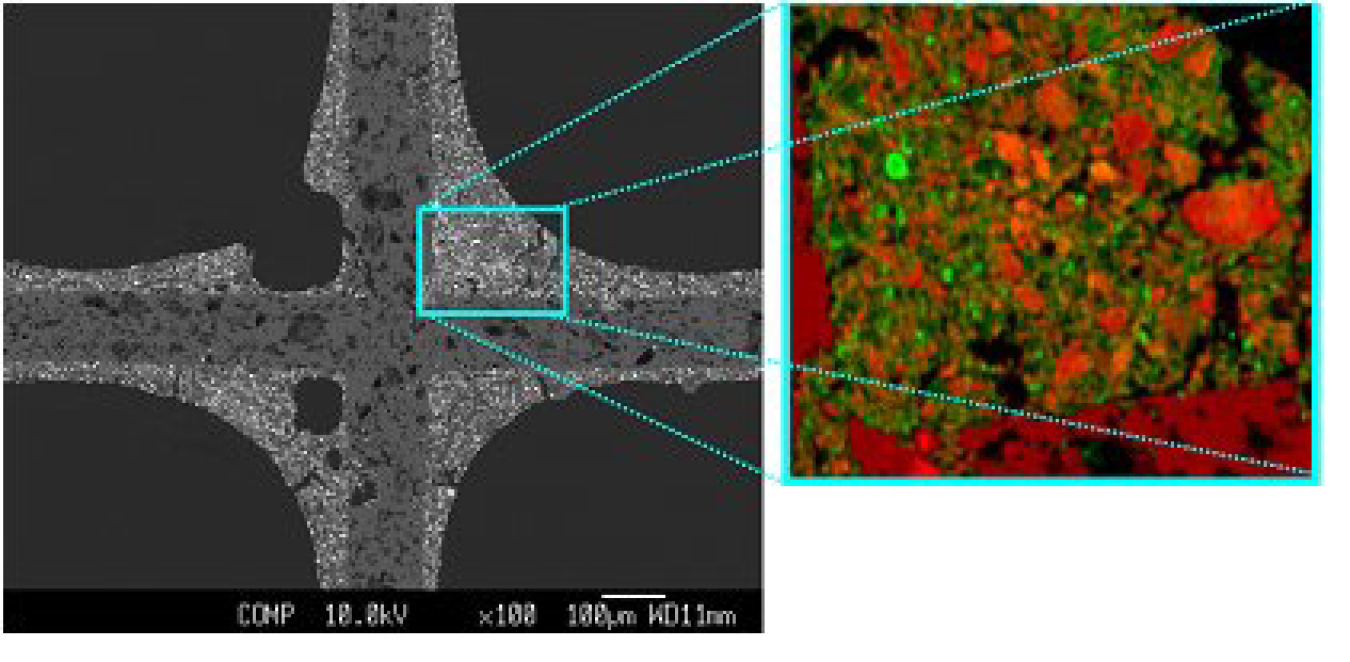

Microscopic analysis techniques on lean NOx trap catalyst elucidate mechanisms of poisoning by Sulfur (green images)

These exhaust aftertreatment technologies include:

- NOx adsorbers and selective catalytic reduction (SCR) to control oxides of nitrogen (NOx)

- Oxidation catalysts to control hydrocarbons (HC)

- Particulate filters to control particulate matter (PM).

VTO's research focuses on overcoming a number of technical issues:

- These technologies become less effective at converting NOx when the engine is at a low temperature (less than 150ºC), which may occur during cold starting or vehicle operation.

- NOx adsorbers incur a fuel economy penalty due to efficiencies that are dependent on temperature. In addition, they are poisoned by sulfur in the fuel and use expensive platinum group metals.

- Urea Selective Catalytic Reduction (urea SCR) technologies lose catalytic activity over time (catalyst deactivation), which decreases their effectiveness. It also creates products of incomplete reactions that can be harmful.

- Hydrocarbon SCR has a limited range of temperatures at which the conversion process is efficient. This technology is also in an early stage of development.

- Particulate filters become clogged and lose effectiveness over time. As such, they require more effective methods to regenerate them than currently exist. They also are not compatible with direct injection gasoline engines and may not be able to meet future regulations for particle number and size distribution.

- Oxidation catalysts lack durability at high temperatures and need to be more efficient at converting HC, CO, and NO to less harmful products.

In addition to overcoming these barriers, VTO's research is developing multifunctional aftertreatment devices that integrate a number of these technologies to improve functionality and reduce the system's cost, weight and volume.

Much of VTO's research works to address needs for future emissions standards that will be more stringent than current regulations (super-ultralow-emission vehicle, SULEV30 and Tier 3). This research:

- Works to develop systems with more than 90% conversion or higher of all emissions below 150ºC

- Studies PM from lean direct injection (DI) gasoline that due to new regulations, are different in size and morphology compared to diesel PM.