The U.S. Department of Energy (DOE) Solar Energy Technologies Office (SETO) supports innovative research focused on overcoming the current technological and commercial barriers for cadmium telluride (CdTe) solar modules. Below is a summary of how a CdTe solar module is made, recent advances in cell design, and the associated benefits. Learn how solar PV works.

What is a CdTe Solar Cell?

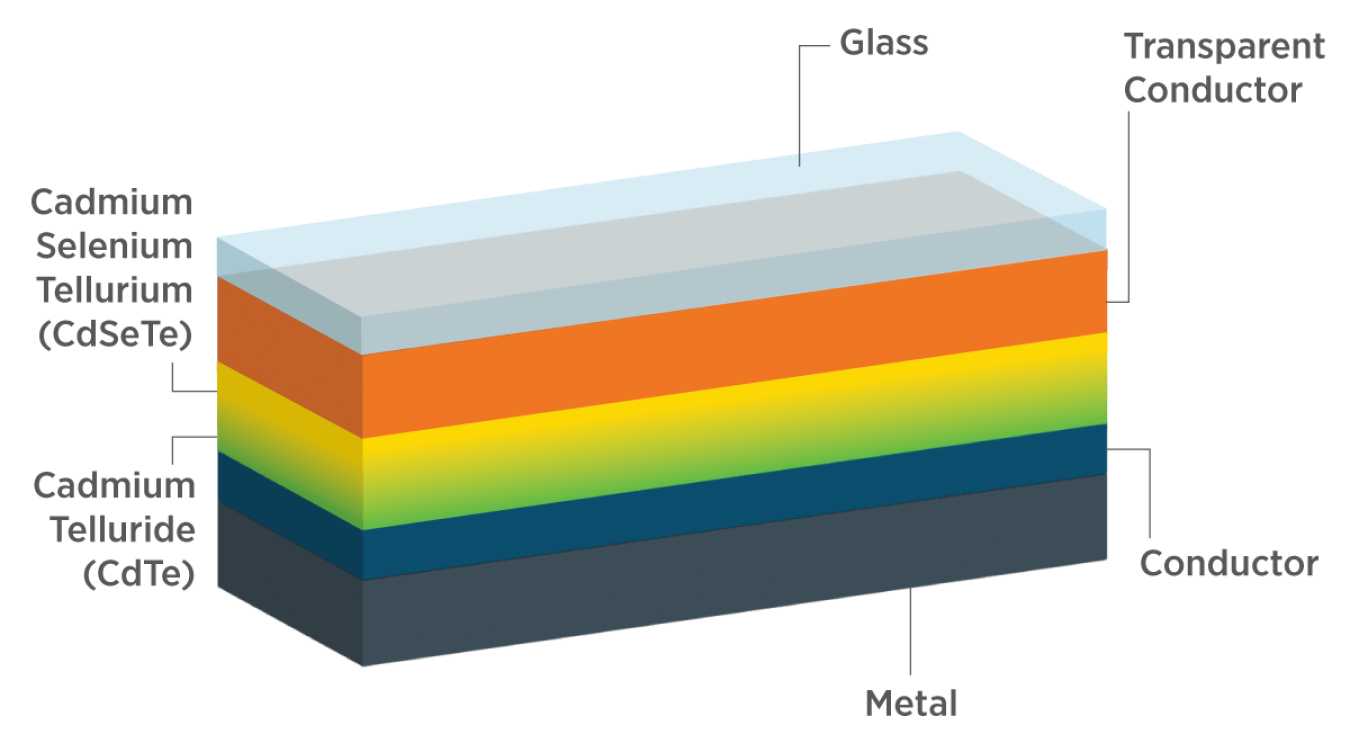

CdTe is a material made from the combination of two elements: Cadmium (Cd) and Tellurium (Te). It plays a critical role of light absorption—hence why a CdTe solar cell is named after it. However, a cell needs more than just the CdTe material to function.

CdTe is a material made from the combination of two elements: Cadmium (Cd) and Tellurium (Te). It plays a critical role of light absorption—hence why a CdTe solar cell is named after it. However, a cell needs more than just the CdTe material to function.

In this “thin-film” technology, a thin layer of CdTe absorbs light, which excites charged particles called electrons; when the electrons move, they create an electric current. CdTe cells are referred to as thin-film because they are more absorptive than other types of photovoltaics (e.g. silicon solar cells) and therefore require thinner layers to absorb the same amount of light.

In a solar cell, the CdTe absorber is attached to other materials, which allows electric current to flow through the absorber layer into the metal contacts and be collected as sustainable electricity. In modern cells, cadmium selenium tellurium (CdSeTe) is often used in conjunction with CdTe to improve light absorption. Learn more about how solar cells work.

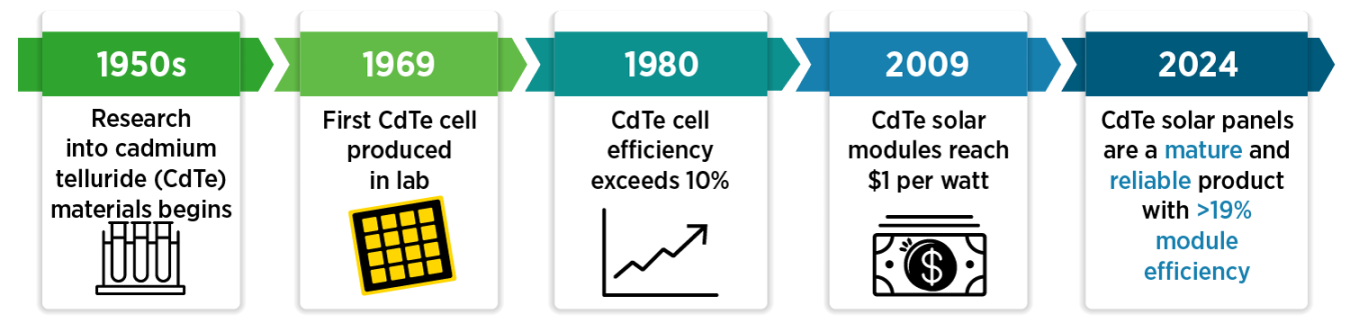

CdTe solar cells are the second most common photovoltaic (PV) technology after crystalline silicon, representing 21% of the U.S. market and 4% of the global market in 2022. In the last 15 years, CdTe deployment has increased from the megawatt scale to the gigawatt scale as modules have more than doubled in efficiency.

How are CdTe Solar Modules Made?

The manufacturing process for cadmium telluride modules can be split into 4 main steps:

Material Production

Cadmium and tellurium are byproducts of mining operations for zinc and copper, respectively. The waste from these mining processes have so far produced more than enough Cd and Te, so no extra mining is needed. The raw materials are refined to create pure Cd and Te.

Cell Production

CdTe vapor is deposited onto a coated conductive glass sheet. Several rounds of laser scribing and material deposition and treatment result in the final cell structure.

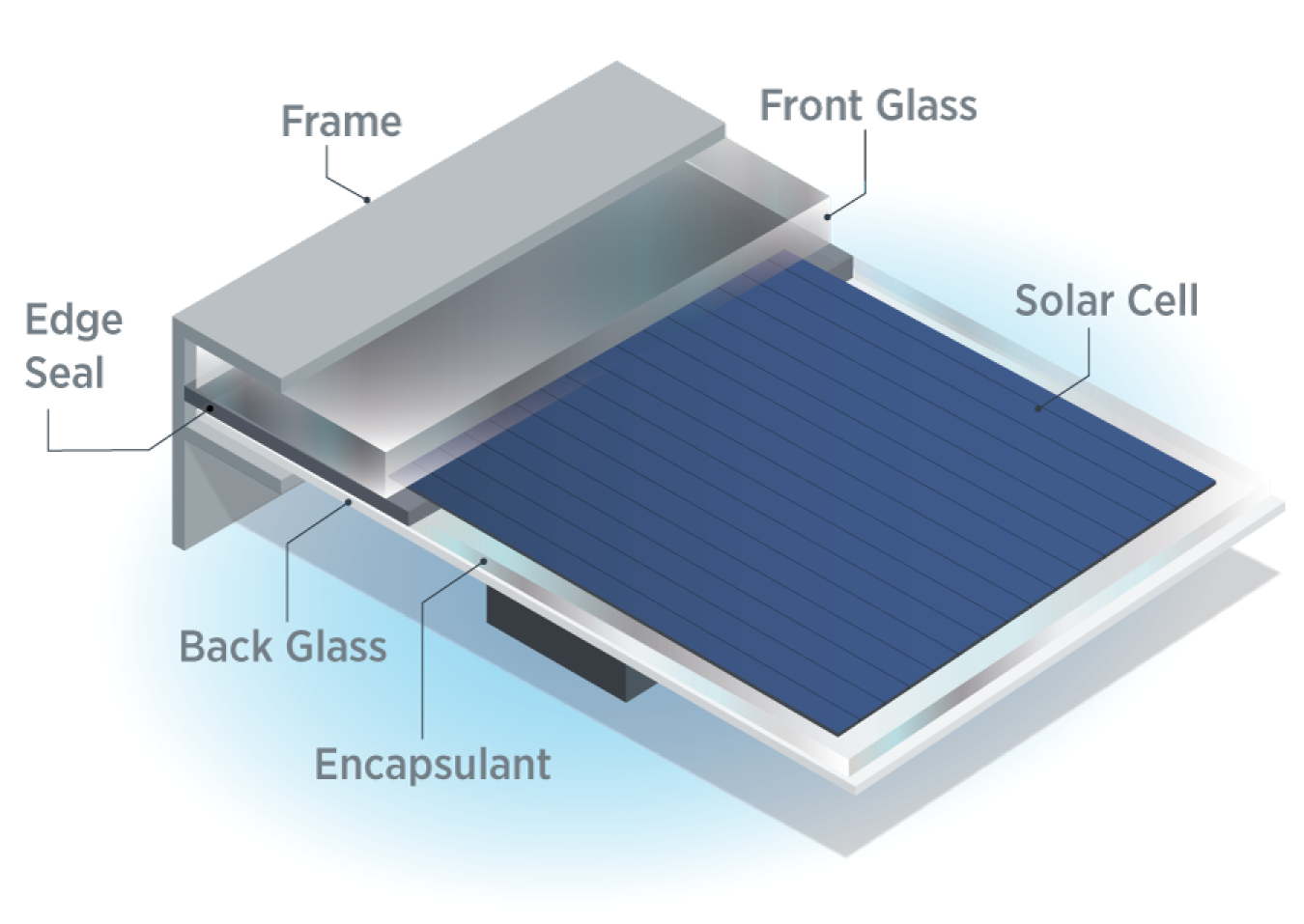

Module Completion

The completed cell is turned into a module by adding electrical contacts to enable wiring to other modules, edge sealant and a layer of encapsulant for weather-proofing, and a final glass backsheet.

Deployment

The module is fit into a frame, attached to other modules, and deployed to start producing clean electricity.

What are SETO research priorities in CdTe?

SETO supports research across all aspects of CdTe technology. Research topics include maximizing the efficiency of CdTe using fundamental science, improving the design of full modules, and assessing the supply chain. SETO investments have helped commercialize CdTe technology. Projects are also developing next-generation cells that combine CdTe with other established PV materials, such as silicon. SETO released the Cadmium Telluride PV Perspective Paper in January 2025, outlining the state of CdTe PV technology and SETO’s priorities to reduce costs, address materials availability, and support the scale-up of CdTe within the domestic utility-scale PV market.

The CdTe Accelerator Consortium is currently SETO’s largest initiative to accelerate CdTe development. Coordinated by NREL, this $20 million collaboration includes five companies and universities working to create a technology roadmap and perform technical research with the goal of increasing CdTe cell efficiencies to 24% by 2025 and 26% by 2030.

Additionally, several of SETO’s funding programs support CdTe technologies:

- Advancing U.S. Thin-Film Solar Photovoltaics

- Small Innovative Projects in Solar (SIPS)

- SETO FY22 Solar Manufacturing Incubator

- Small Business Innovation Research/Small Business Technology Transfer (SBIR/STTR)

- SETO FY22-24 Lab Call

Learn more about the SETO’s CdTe projects in the Solar Energy Research Database.

What are the Benefits of CdTe Solar Cells?

| Manufacturing Efficiency | With high-throughput manufacturing methods, a CdTe module can be produced in under 4.5 hours. |

| Low Environmental Impact | CdTe module production requires 6 times less carbon dioxide than silicon. Once decommissioned, more than 90% of a CdTe module can be recycled. |

| Light Absorption | The material properties of CdTe maximize the proportion of the light spectrum that can be absorbed. CdTe is also a “direct bandgap” semiconductor, meaning it can absorb that light more efficiently. |

Learn more about SETO’s PV research and how PV technologies work.