EERE Success Story—3D Printing Enables New Generation of Heat Exchangers

March 17, 2016

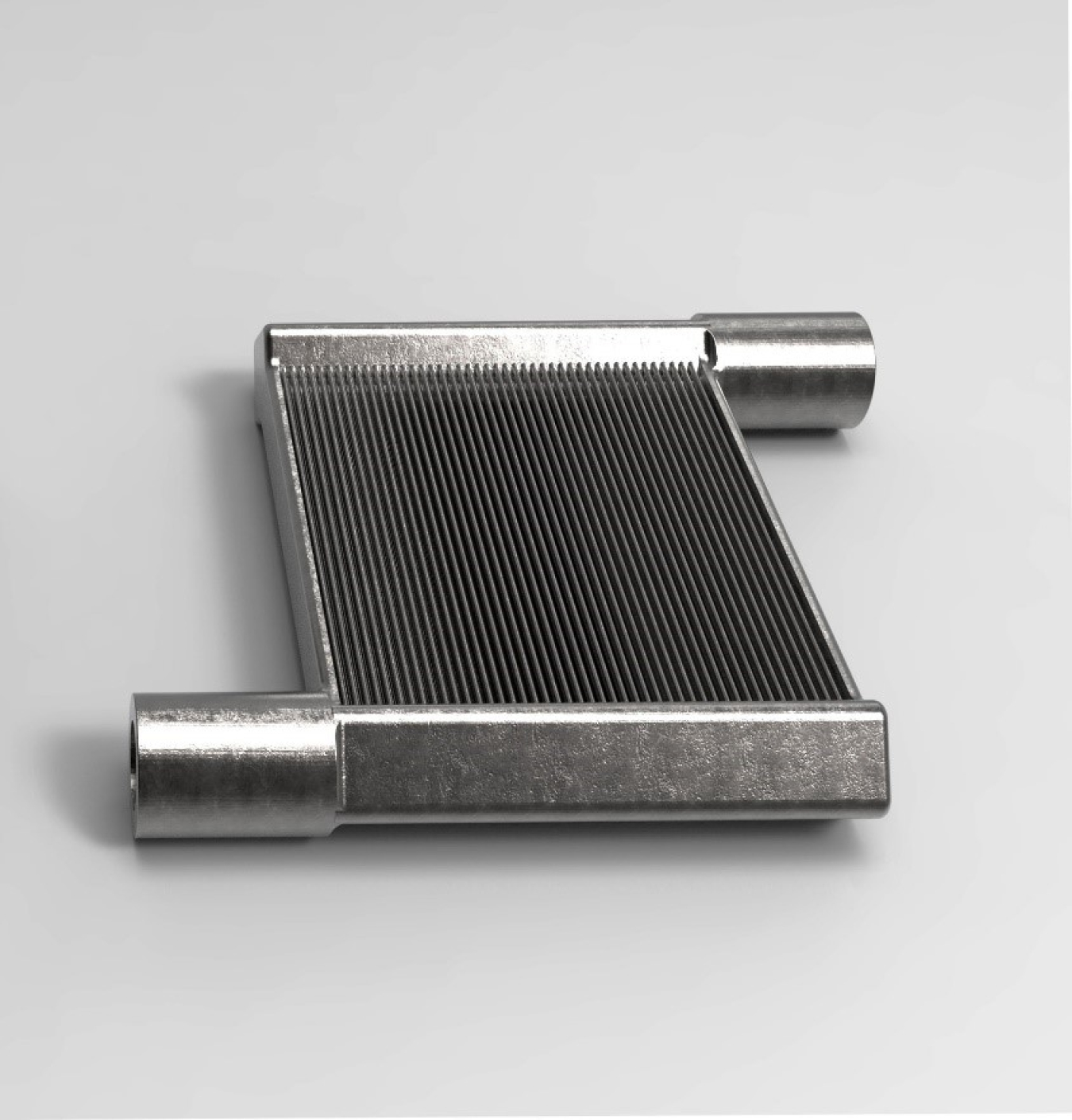

The University of Maryland used direct metal printing—a 3D printing technology—to manufacture a unique miniaturized air-to-refrigerant heat exchanger as a single, continuous piece. Image: University of Maryland, Center for Environmental Energy Engineering.

Technology History

- Builds on previous University of Maryland research exploring innovative heat exchanger designs

Partners

- University of Maryland, College Park

- Oak Ridge National Laboratory

- 3D Systems

- Burr Oak Tool

- Luvata

- International Copper Association

- Wieland

- Heat Transfer Technologies

Applications

- Residential and commercial air conditioners and heat pump systems

Benefits

- 20% increase in heat exchanger efficiency

- Reduced weight and size of heat exchanger

- 3D printing enables unique, intricate designs not possible with other manufacturing methods

DOE Funding

- $1.5 million

Contact

- Tony Bouza, DOE

Three-dimensional printing is revolutionizing how we manufacture objects in almost every industry—from vehicles to medical devices to biotech. Now, the University of Maryland, through a partnership with 3D Systems and the U.S. Department of Energy’s Building Technologies Office, has used 3D printing to prototype one of the most important enabling technologies in a building—the heat exchanger. This next-generation heat exchanger weighs 20% less, performs 20% more efficient, and can be manufactured much quicker, compared to current designs.

Heat exchangers play a vital role in the modern world—almost any time heating or cooling is needed, a heat exchanger is used. Quite literally, it exchanges heat from one area to another. On a global scale, heat exchange is a multi-billion-dollar industry, touching everything from consumer goods to automotive and aerospace engineering. In other words, improving the performance of a heat exchanger can improve the performance of millions of products.

There were several advantages 3D printing offered University of Maryland researchers when it came time to time to prototype their innovative designs for a better performing heat exchanger.

Modernizing an Outdated Process

For decades, manufacturers have been using a type of heat exchanger known as tube-fin—without any significant changes. While new, high performing designs existed, companies had struggled to commercialize them—they were too complex to be economically manufactured with traditional processes.

But unlike traditional manufacturing, 3D-printing a complex design costs no more than 3D-printing a simple one. 3D Systems’ direct metal printing process allowed researchers to use non-conventional, variable shapes that increase the heat exchanger’s efficiency.

University of Maryland researchers were also able to speed up their design process thanks to 3D printing. Typically, the manufacturing process for a prototype of a unique and high performing design can take months; by using 3D printing, researchers completed the process in weeks. This efficiency enabled researchers to test the new designs earlier and more frequently during the project.

Improved Performance, Less Waste

The University of Maryland team optimized their heat exchanger design so it could be printed in a single, continuous piece. As a result, prototypes are increasingly resistant to pressure or leakage, resulting in improved performance and reliability—and ultimately, a more efficient system heating or cooling your home.

Because the heat exchanger is being printed as a singular piece with proven materials, this ensures very little waste material is generated—saving money for manufacturers, while reducing their environmental footprint.

What’s Ahead?

The heat exchanger, which acts as both an evaporator and a condenser, can be used in commercial and residential air-conditioning or heat pump systems of varying sizes. The University of Maryland’s new 1 kilowatt (kW) miniaturized air-to-refrigerant heat exchanger prototype paves the way for new designs that will help reduce the nearly 7 quads of energy that is annually used for heating, ventilation, air conditioning, and refrigeration in the United States.

In addition to the 1kW model, a 10kW prototype will also be fabricated as part of the current project. Both prototypes will be tested and demonstrated in a three-ton heat pump. The University of Maryland research team expects the new heat exchangers will be in commercial production within five years.

The Office of Energy Efficiency and Renewable Energy (EERE) success stories highlight the positive impact of its work with businesses, industry partners, universities, research labs, and other entities.