Enhanced geothermal systems (EGS), or human-made geothermal energy, holds the potential to power American homes and businesses nationwide and is the next frontier for geothermal energy deployment. The Office of Geothermal (OG) EGS program supports research, development, and demonstration projects that guide enhanced geothermal technologies towards commercial viability.

What is an Enhanced Geothermal System (EGS)?

A naturally occurring geothermal system, known as a hydrothermal system, requires three key elements to generate electricity: heat, fluid, and permeability, which is when fluid can move freely through the underground rock.

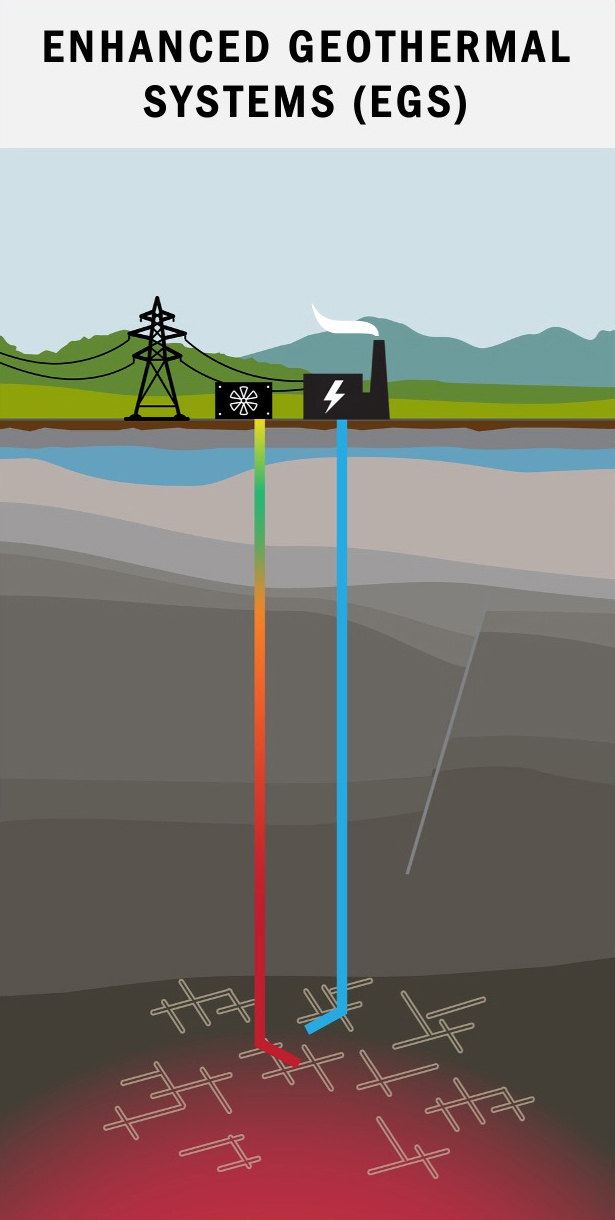

In many areas, however, the underground rock is hot but there is not enough natural permeability or fluids present. In those cases, an enhanced geothermal system (EGS) can be used to create a human-made reservoir to tap that heat for energy.

In an EGS, fluid is injected deep underground under carefully controlled conditions to create new fractures and cause pre-existing fractures to re-open, creating permeability. Increased permeability allows fluid to circulate throughout the more fractured hot rock, and the fluid becomes hot as it circulates. Operators pump the hot water up to the surface, where it generates electricity for the grid. Watch a video to learn more about the steps and benefits in EGS development.

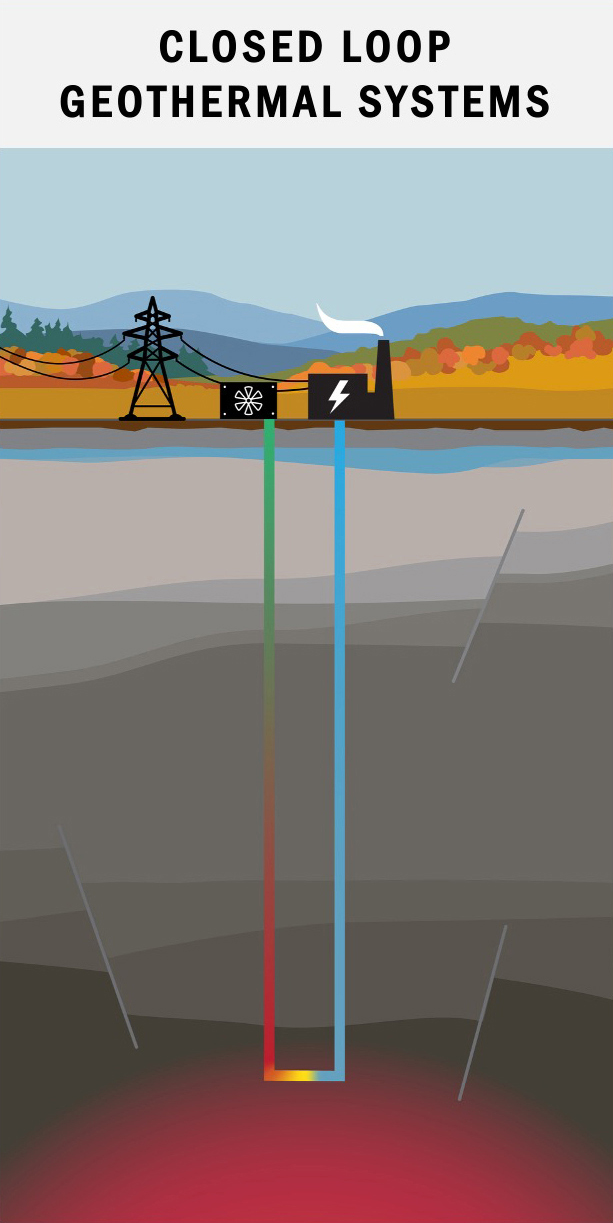

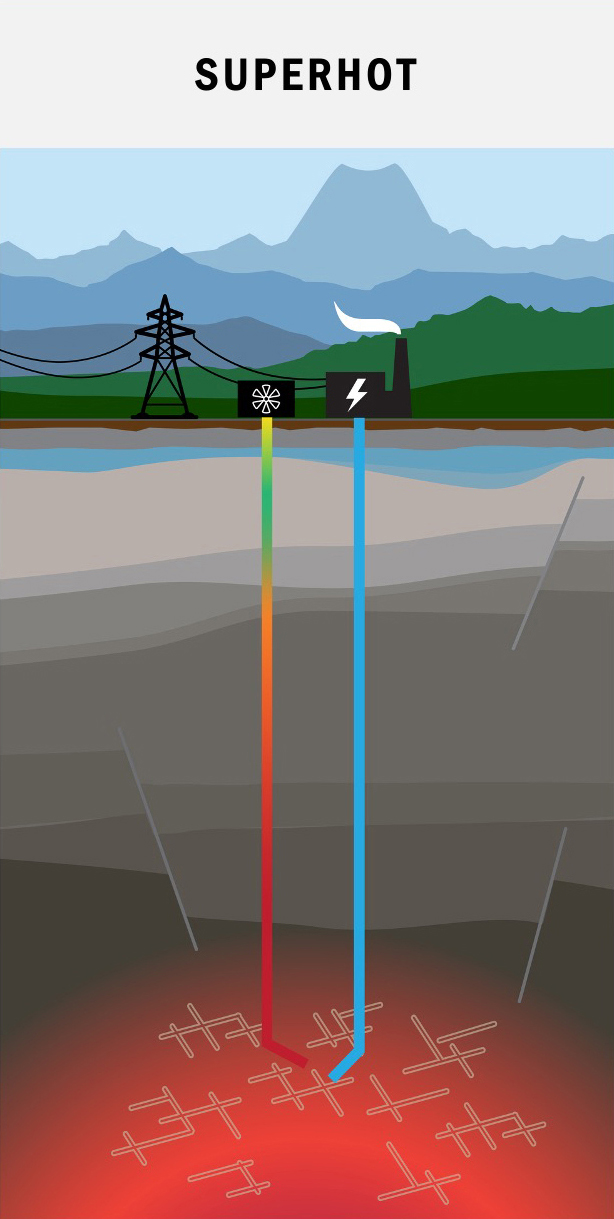

Other next-generation geothermal power generation technologies include closed loop geothermal systems and superhot geothermal systems. Closed loop geothermal systems do not rely on a fracture network. Instead, these systems are somewhat akin to a “radiator”—a series of closed pipes underground that circulate water and working fluids to absorb heat from the subsurface and bring it to the surface to produce power. Superhot geothermal systems tap resources at >375°C. Water injected into these extremely hot environments becomes so hot that it has the properties of both liquids and gases, allowing the superheated water to gather very large volumes of heat energy. At the surface, it can be used to produce power at several times the power density (amount of power per unit volume) than lower-temperature rock.

EGS and other next-generation geothermal technologies could facilitate geothermal development beyond traditional hydrothermal regions, thereby extending geothermal energy production nationwide. EGS advances are being demonstrated worldwide today, in both the public and private sectors.

Office of Geothermal EGS Efforts

EGS Demonstration Projects

In the United States, the U.S. Department of Energy (DOE) Office of Geothermal (OG) currently funds a major EGS demonstration in Milford, Utah: The Frontier Observatory for Research in Geothermal Energy (FORGE). At the site, researchers have already demonstrated significant improvements in drilling rates and successful rock stimulation.

DOE also previously funded two successful EGS demonstration projects:

- Desert Peak, Nevada: Ormat Technologies stimulated a non-commercial well on the periphery of its operating conventional geothermal system at Desert Peak, Nevada. The stimulation successfully created an EGS reservoir and added 1.7 megawatts (MW) of electricity production at the existing geothermal power plant.

- The Geysers in Northern California: Calpine, the operators of The Geysers geothermal field, deepened and stimulated two previously abandoned geothermal wells. The refurbished wells added 5.8 MW of power to existing generation. Watch a video of geothermal drilling at The Geysers (view transcript here).

OG is currently supporting projects to conduct EGS pilot demonstration projects and demonstrate EGS in a variety of geographic locations, geologic formations, and subsurface conditions. This work will advance EGS and other next-generation geothermal technologies, bolster the U.S. geothermal industry and help the nation realize the vast potential of geothermal energy to provide firm, flexible, power and heat nationwide.

Learn more about OG’s EGS demonstration projects.

Next-Generation Geothermal Field Tests and Geothermal Resource Characterization and Confirmation

Funding of up to $171.5 million will advance next‑generation geothermal field tests and exploration drilling for both emerging and conventional hydrothermal resources. This NOFO seeks to address key technology and exploration gaps, with up to 28 anticipated awards ranging from $4–$25 million and an open period of up to 72 months. Learn more about the Notice of Funding Opportunity topic areas, expected funding, and how to apply.

Well Construction and Evaluation

A key requirement for expanding the use of EGS is reducing the costs and technical challenges associated with constructing wellbores. In particular, wellbore casing and cementing materials and operations represent around 30% to 40% or more of overall well costs. Reducing these costs requires finding better means by which to evaluate performance during construction and operation. Available off-the-shelf solutions for well cement and casing evaluation are suitable for the upper end of the oil and gas industry’s temperature needs, but not generally considered adequate for hotter geothermal systems. Improving methods to build wells and assess their performance can reduce costs for EGS and other geothermal power generation technologies, helping make geothermal electricity more cost-effective.

Wells Of Opportunity

A key step to unlocking the full potential of reliable, domestic geothermal energy may lie inside millions of American oil and gas wells. These wells can be used to harness geothermal energy in two ways: through the retrofitting of inactive or unproductive wells, or through co-production on active wells. OG is exploring both methods with the Wells Of Opportunity (WOO) initiative which will help establish the commercial viability of geothermal energy production from existing hydrocarbon fields.

Additional EGS Initiatives and Technical Resources

Performance Evaluation of Engineered Geothermal Systems Using Discrete Fracture Network Simulations

For more information, contact DOE.Geothermal@ee.doe.gov.

Successes from American-Made Prizes

Innovations to “Hear” the Subsurface

The Geothermal Geophone Prize is a three-phase, $3.65 million competition to address the challenges of operating seismic sensors in harsh geothermal environments that launched in April 2022. These sensors collect data about geothermal reservoirs and subsurface conditions, which is essential to develop successful and efficient human-made enhanced geothermal systems, but traditional seismic monitoring tools cannot withstand the high temperatures, high rock strengths, and corrosive working fluids in geothermal wells. The prize received numerous promising geophone designs for high-temperature use in Phase 1 and Phase 2. At the end of the first phase of the competition, the quality of submissions was so high that OG and prize administrators decided to select 10 semifinalists instead of the originally planned eight. In the second phase, in addition to receiving submissions from all the semifinalists, OG also received two submissions from non-winning teams who wanted to continue pursuing work on their prototypes. OG announced the finalists in the competition in March 2024.

Additive Manufacturing to Support Next-Generation Geothermal Technology

The Geothermal Manufacturing Prize was a $4.65 million competition to incentivize innovators to use 3D printing, or additive manufacturing, to address the challenges associated with operating sensitive equipment in harsh geothermal environments. One of the two winning teams of the prize, Team Ultra-High Temperature Logging Tool (Team UHTLT), flipped the concept of high-temperature tools on its head with their prototype design for this competition. Instead of pursuing new approaches to harden the electronics themselves, the team looked to use off-the-shelf electronics and design a completely new thermal insulation system that allows off-the-shelf equipment to thrive in environments where it previously could not. The team’s new design also cuts down the typical deployment innovation time for high-temperature electronics from five years or more to less than two years.

In August 2023, Team UHTLT successfully tested their winning prototype in a commercial partnership with power producer Calpine Corporation at The Geysers geothermal field in California, demonstrating the tool's ability to deploy at realistic temperatures (> 200◦C) and pressures, log important downhole information including well temperature profiles, and validate the heat sink design built as part of the prize competition. In fact, the team managed to log four successful temperature runs in three days on a testing well that the site operator had been unable to measure. This testing has proven Team UHTLT’s business case, and they are continuing to commercialize their technology in partnership with Calpine.

OG emails bring geothermal funding opportunities,

events, publications, and activities directly to your inbox.