Lead Performer: Oak Ridge National Laboratory - Oak Ridge, TN Partner: GE Appliances - Louisville, KY

July 23, 2014

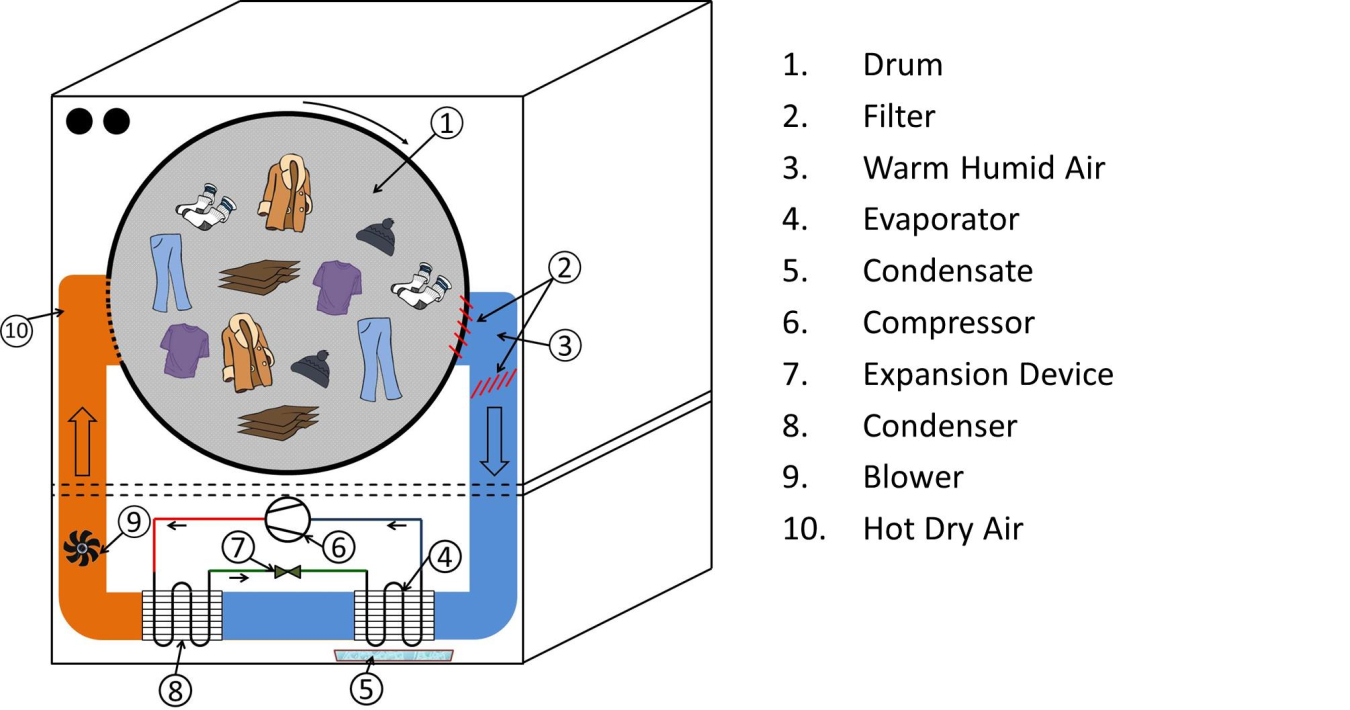

Schematics of a heat pump clothes dryer.

Lead Performer: Oak Ridge National Laboratory - Oak Ridge, TN

Partner: GE Appliances - Louisville, KY

DOE Funding: $1,000,000

Cost Share: Provided by CRADA partner

Project Term: October 2013 - September 2016

Project Objective

The central objective of this project is to design and develop a heat pump clothes dryer for the U.S. housing market. ORNL will conceptualize a heat pump dryer with and/or without an energy recovery heat exchanger and alternate refrigerants. The clothes dryer design will focus on developing a heat pump cycle to provide heat input for the drying process. This product offers the advantages of lower energy consumption and no moisture disposal issues over the conventional electric dryers. Some of the challenges to address include higher initial cost, fouling of heat exchangers, lower capacity and longer cycle time. The heat pump clothes dryer has the potential of lowering the energy consumption by 60% as compared with the conventional resistance heaters. Appropriate prototype(s) will be developed and tested inside the laboratory.

Project Impact

In the U.S., the majority of clothes dryers use electric resistance heaters with a capacity of approximately 4 kW for clothes drying. These dryers consume about 71 TWh/year in the U.S. or approximately 4% of the total annual residential electricity use [USDOE EIA 2010]. ORNL estimates this heat pump dryer will save approximately 25.8 TWh per year when the new technology is fully deployed nationwide [UMD, 2013].

References:

- U.S. DOE EIA. 2010. Annual Energy Outlook 2010 (Early Release) with Projections to 2035, 2010. Washington, D.C. Report No. DOE/EIA-0383(2010).

- University of Maryland 2013, Two stage heat pump clothes dryer, Max Tech and beyond appliance design competition for ultra-low-energy use appliances and equipment for AY2012-2013, A technical report submitted by University of Maryland, June 24, 2013.

Contacts

DOE Technology Manager: Tony Bouza

Performer: Kyle Gluesenkamp, Oak Ridge National Laboratory