Across the nation, scientists are on a mission to produce affordable and sustainable biofuels and products from algae, including jet fuel and plast...

Office of Critical Minerals and Energy Innovation

September 23, 2016

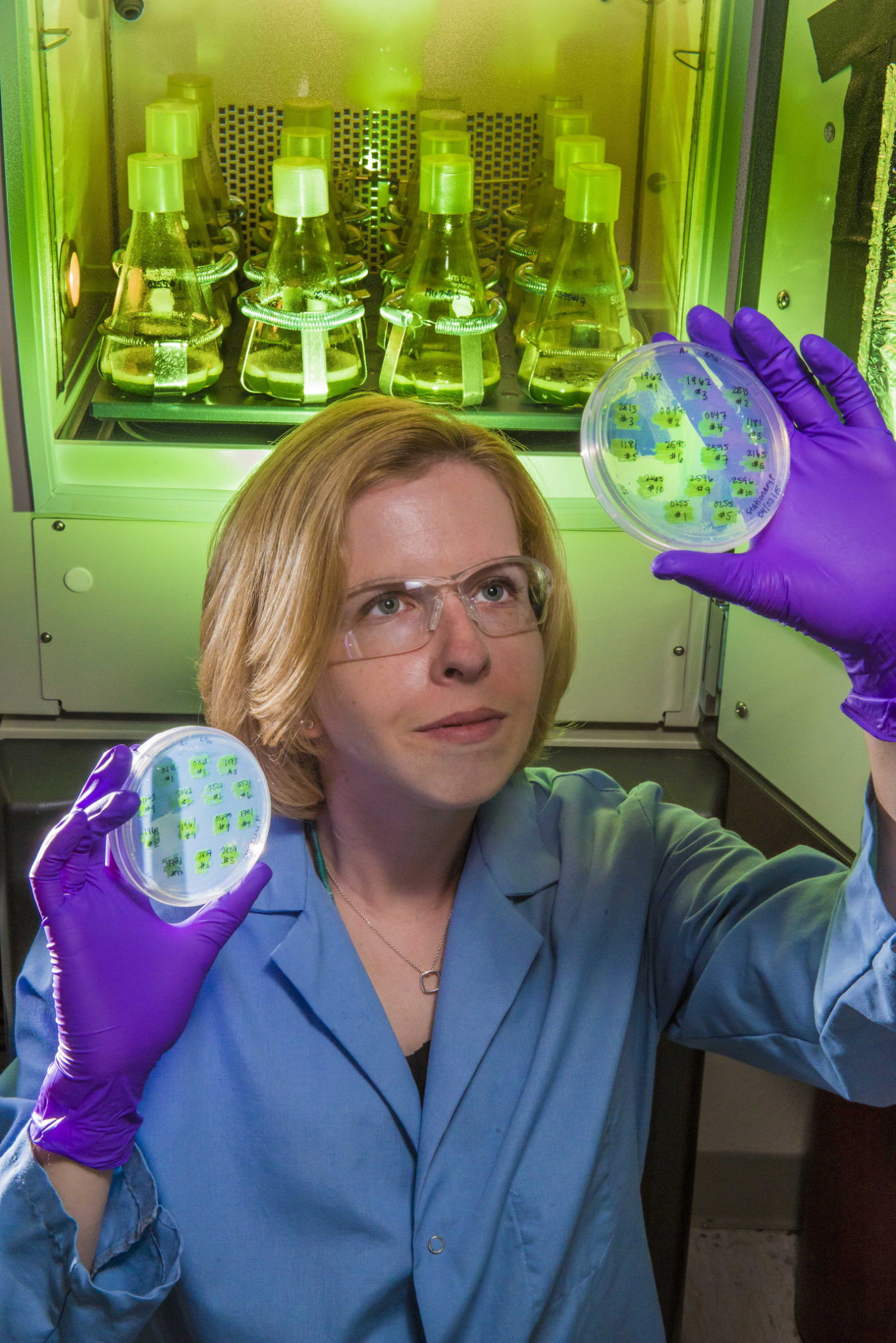

Engineer studies modification of algae for biofuel production. | Photo courtesy of Sandia National Laboratories

Across the nation, scientists are on a mission to produce affordable and sustainable biofuels and products from algae, including jet fuel and plastics. Algae grow fast, utilize carbon dioxide, and can produce high levels of oils that can be converted to transportation fuel—making them an excellent renewable fuel source.

However, to produce biofuel from algae on a commercial scale, producers must optimize algae growth in large cultivation systems, which may be expensive to construct and operate. Harvesting the algae and preparing them to be converted into biofuels can also be costly and energy-intensive processes. These costs need to be reduced to make algal biofuels commercially viable.

Luckily, algae scientists funded by the Energy Department’s Bioenergy Technologies Office (BETO) have been busy expanding the tools available to support breakthroughs in biology that could lead to major improvements in algae growth and productivity—making algal biofuel more cost-effective. Advances in the broader biotechnology industry are making these improvements possible now more than ever before.

Here are some new tools that algae scientists are putting into their “toolbox:”

Screening tools

Scientists are developing equipment to screen the thousands of species of naturally occurring algae, as well as the millions of algae strains that can rapidly be produced in the lab. Screening algae helps scientists to identify which algae grow more quickly and produce more energy. Algae’s incredible biological diversity opens up potential to produce dozens of different types of products, since one algae strain may naturally produce more lipids and another strain may produce more of another product such as proteins. Isolated algae strains are accessible to researchers through collections such as the University of Texas Culture Collection of Algae.

Genetic tools

Using newly discovered genetic modification techniques, scientists are working to precisely insert, delete, and control certain genes in algae in order to give algae the ability to grow more quickly and produce more fuel. This knowledge and engineering of algae can create higher resistance to pests and higher tolerance to environmental conditions, such as extreme temperatures.

Characterization tools

Once promising strains of algae are identified or created, they must be fully characterized, which means to gather information about their characteristics, such as their productivity, how they grow best, and what products they can make. Modeling and other tools allow fast and affordable ways to evaluate each algae strain’s productivity and predict how each strain will grow in large-scale outdoor areas.

Big data tools

All of the research that goes into determining the algal genomes, as well as screening and evaluating the many species and strains of algae, results in an enormous amount of data that needs to be organized and easily accessible. There is not only a large volume of data, but a large variety—ranging from the results of outdoor growth experiments to genetic and characteristic information from new species of algae.

Scale-up tools

In the end, what works in the lab must be validated in real-world conditions. Algae developers are using a combination of modeling, indoor test platforms, and larger open ponds to achieve improvements in outdoor algae cultivation.

BETO hosted the Algal Biology Toolbox Workshop this past May to discuss how to sharpen these tools to reduce the cost of biofuel production. Algal biologists, chemical engineers, business developers, and others came together in San Diego, California—a hub for algal biotechnology in the United States. The recently released workshop summary report provides an overview of the current state of algae research, as well as attendee recommendations for future development priorities. BETO’s Advanced Algal Systems Program regularly hosts stakeholder events to gain input on the research and development needed to bring sustainable algae-based biofuels to market.

Algal biofuels and bioproducts are an important part of BETO’s vision for a thriving and sustainable U.S. bioeconomy fueled by innovative technologies.

More by this author

-

Program Manager, Feedstock Supply and Logistics and Advanced Algal Systems, Bioenergy Technologies Office

Program Manager, Feedstock Supply and Logistics and Advanced Algal Systems, Bioenergy Technologies Office