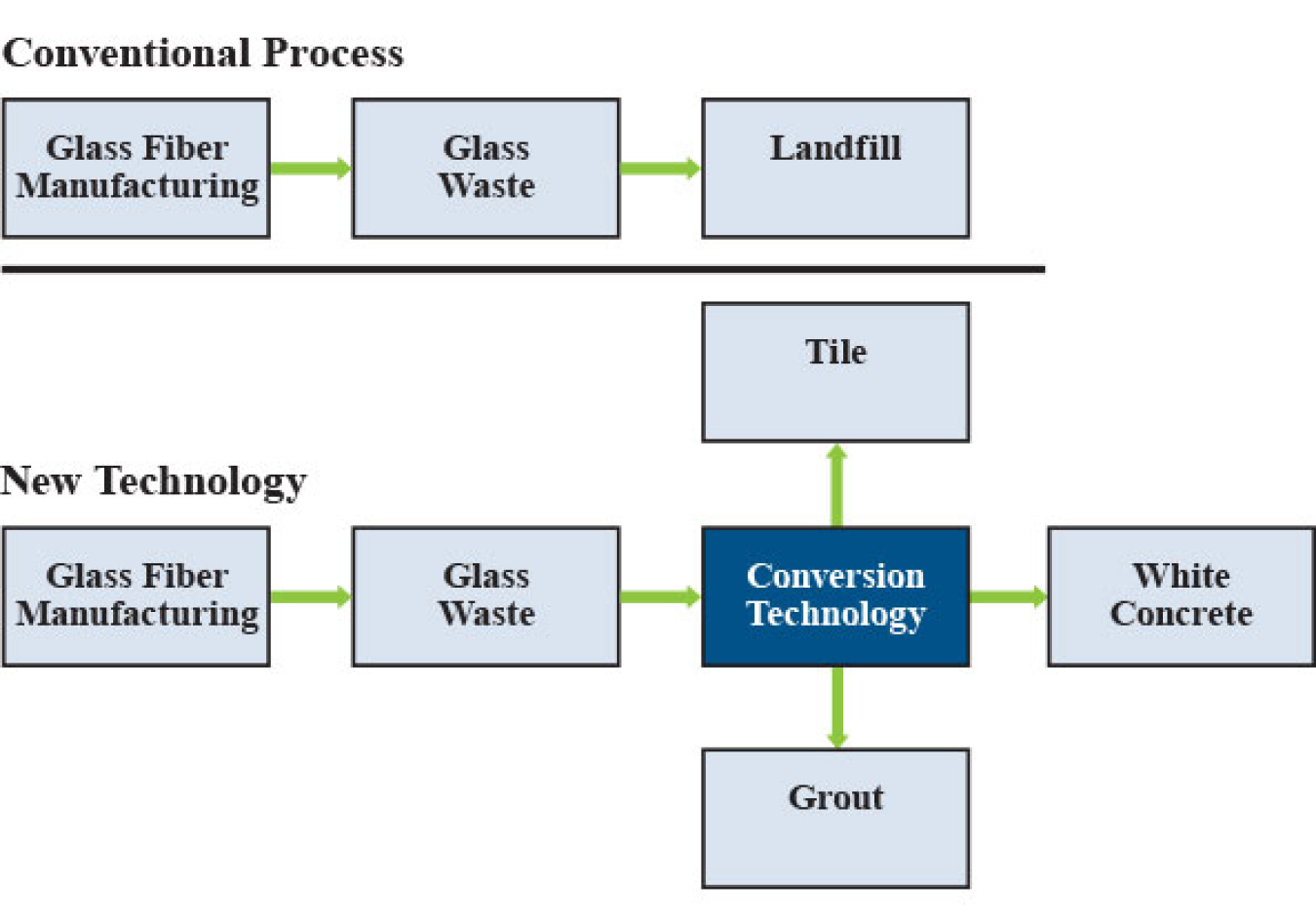

New Process Reduces Glass Fiber Waste Stream to Landfills

Solid wastes are generated at glass fiber manufacturing facilities. With the help of a grant from DOE’s Inventions and Innovation Program, Albacem, LLC, developed a new process that converts these waste streams into VCAS™ (vitrified calcium aluminosilicate) pozzolans that can be used in cement and concrete applications. This technology can help divert up to 250,000 tons per year of discarded glass fiber manufacturing wastes for use in the concrete construction industry. This technology can also be used for processing glass fiber waste materials reclaimed from existing landfills at manufacturing facilities. Both sources can help supply over 500,000 tons per year of glass fiber waste for processing into value-added products.

In the new process, waste glass fiber is ground to a fine powder that effectively functions as a reactive pozzolanic admixture for use in Portland-cement-based building materials and products, such as concrete, mortars, terrazzo, tile, and grouts. Because the waste fiber from the glass manufacturing industry is vitreous, clean, and low in iron and alkalis, the resulting pozzolan is white and highly consistent in chemical composition. This white pozzolan is especially suited for white concrete applications, providing increased long-term strength and improved long-term durability. This new pozzolan is being manufactured and marketed by Vitro Minerals Inc. While this additive is targeted toward white concrete applications, it can also be applied to other concrete applications where environmental benefits are desired.

Impact of Commercialized Technology

| 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | ||

|---|---|---|---|---|---|---|---|

| Energy Savings (Trillion Btu) | 0.070 | 0.070 | 0.105 | 0.140 | 0.140 | 0.140 | |

| Emissions Reductions (Thousand Tons) | Carbon | 1.111 | 1.111 | 1.667 | 2.222 | 2.222 | 2.222 |

| NOx | 0.008 | 0.008 | 0.012 | 0.016 | 0.016 | 0.016 | |

| SOx | 0 | 0 | 0 | 0 | 0 | 0 | |

| Particulates | 0 | 0 | 0 | 0 | 0 | 0 | |

OVERVIEW

- Developed by Albacem, LLC.

- Commercialized and marketed by Vitro Minerals in 2006.

APPLICATIONS

Can be used for waste streams in the glass fiber industry and to replace part of the cement used in concrete.

CAPABILITIES

- Decreases water used to cure concrete.

- Imparts white color to concrete.

BENEFITS

Energy Savings

Decreases the amount of cement used in concrete and the amount of water needed to cure concrete while imparting white color to the concrete.

Environmental

Reduces the carbon footprint of a product when used as a cement additive.

Waste Reduction

Reduces the waste stream from current glass fiber manufacturing and reclaims glass fiber waste from old landfills.

CONTACT INFORMATION

Raymond T. Hemmings, PhD

(770) 590-1560

hemmings@earthlink.net

Albacem, LLC