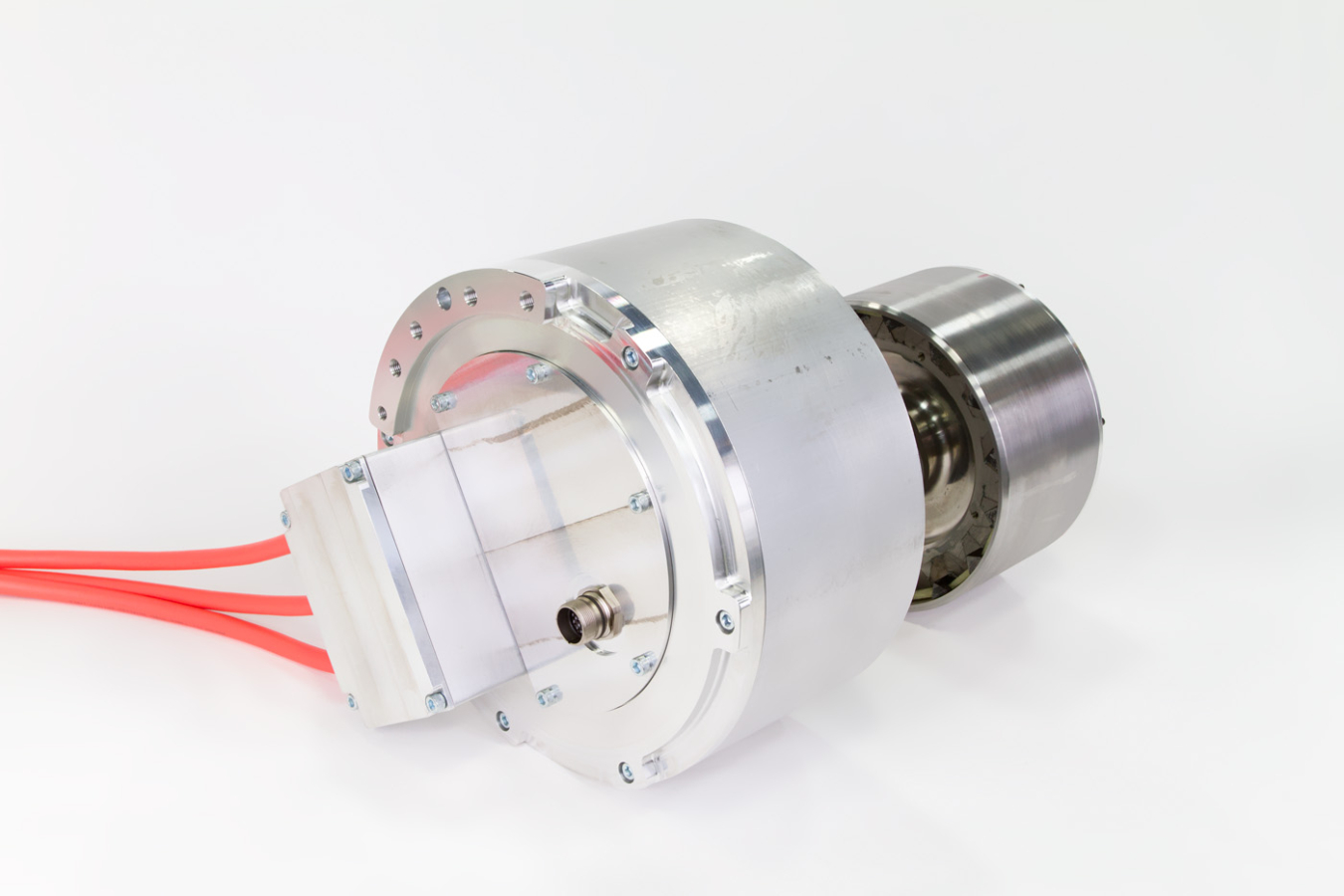

Credit: UQM Technologies

Through a cooperative R&D project with the Vehicle Technologies Office (VTO), UQM Technologies, a company developing propulsion systems for electric, hybrid electric, plug-in hybrid electric and fuel cell electric vehicles recently patented a new design for electric vehicle motors that use non-rare earth magnets.

While most plug-in electric vehicles (PEVs) use motors with rare earth metals, these materials are expensive, their prices have been highly volatile (from $80/kg to $750/kg), and their supply may fall short with potentially high market demand in the future. Electric motors that do not use rare earth metals will potentially be less expensive and have more stable prices. Non-rare earth motors may also rely more on domestic resources and processing capabilities, which could improve economic, environmental and energy security. Reducing the use of rare earth metals in PEVs can help VTO reach the EV Everywhere Grand Challenge goal of making PEVs as affordable as today’s gasoline powered vehicles by 2022.

UQM’s new motor design performs comparably to rare-earth motors, helping the company meet VTO’s size, weight, and efficiency targets. It also provides the company flexibility to adapt to the market. Once UQM develops the design, it can either use the original rare earth-based design or the new one, depending on the price and availability of rare earth materials.

This patent is based on research supported by a $4 million project, with $2.6 million provided by VTO. UQM is collaborating with DOE’s Ames National Laboratory to improve the magnets’ properties, the National Renewable Energy Laboratory to develop thermal management approaches, and Oak Ridge National Laboratory to test the motor. For more information on this project, see the company’s 2014 presentation at the VTO Annual Merit Review and Peer Evaluation.

In addition to this research, VTO previously supported a UQM component manufacturing project that increased the volume of electric motor and power electronics production. The project allowed the Colorado-based company to establish manufacturing lines that can build at least 20,000 units annually. The company is currently supplying motors to transit bus company Proterra and has supply agreements with energy management and vehicle companies around the world.

The EV Everywhere Grand Challenge focuses on the U.S. becoming the first nation in the world to produce plug-in electric vehicles that are as affordable for the average American family as today's gasoline-powered vehicles by 2022. The Vehicle Technologies Office (VTO) develops and deploys efficient and environmentally friendly highway transportation technologies that will enable America to use less petroleum. These technologies will provide Americans with greater freedom of mobility and energy security, while lowering costs and reducing impacts on the environment.

The Office of Energy Efficiency and Renewable Energy (EERE) success stories highlight the positive impact of its work with businesses, industry partners, universities, research labs, and other entities.