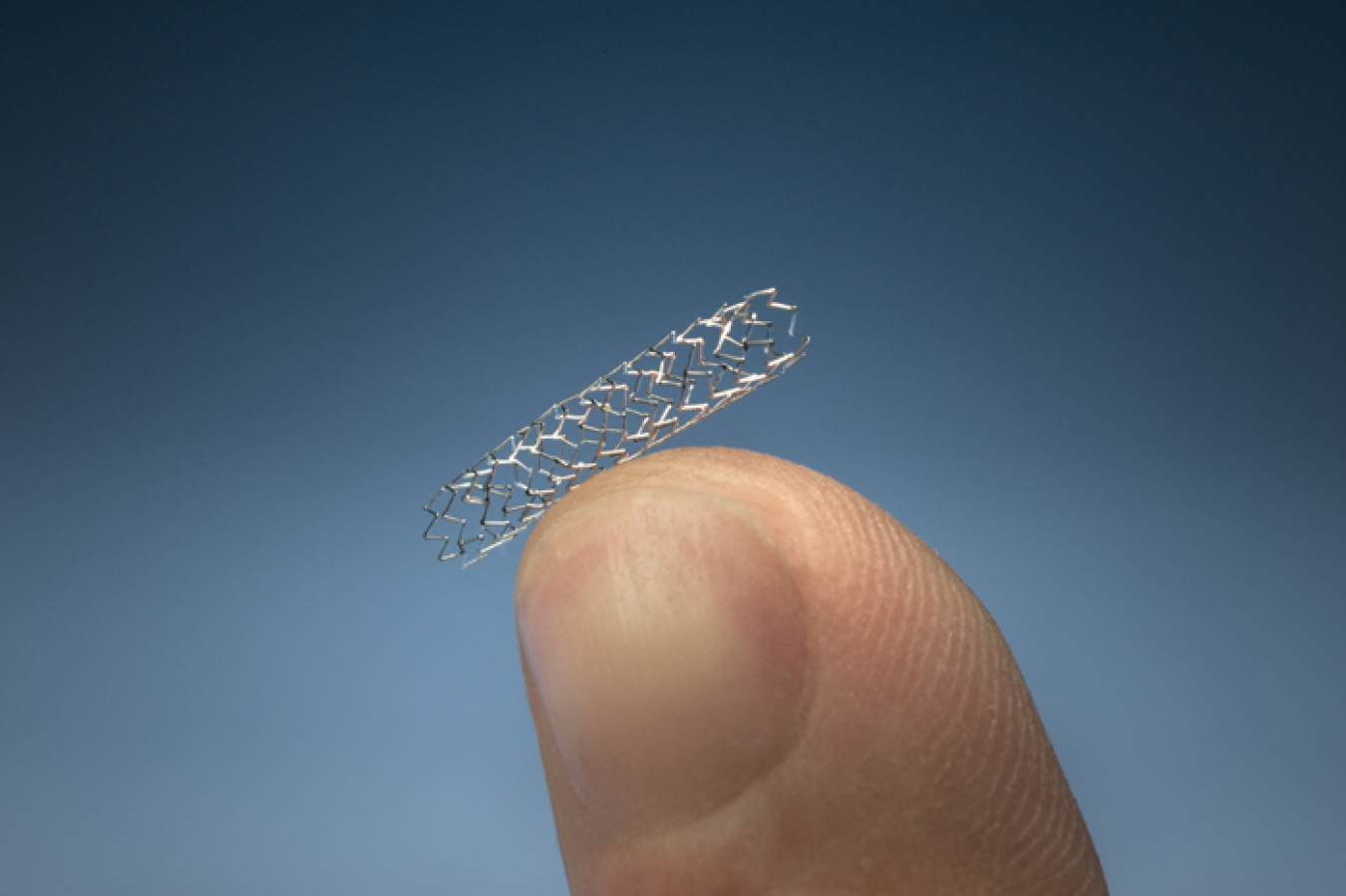

Balanced on the tip of a finger, it doesn’t look like much — a bit of screen door, perhaps, or a badly mangled paper clip — but this little piece of metal is making big news in the medical community, and big changes in the lives of patients with coronary- and peripheral-artery disease.

What it is, is a stent — specifically a stent made of a unique platinum-chromium alloy developed by researchers at the National Energy Technology Laboratory (NETL) and Boston Scientific.

Stents are tiny mesh tubes that doctors carefully insert into narrowed or weakened arteries to keep the blood flowing. For decades, 316L stainless steel was the alloy of choice as newly designed stents were made thinner and thinner, making them more flexible. But flexibility came at a cost. As stents became thinner, they also became more difficult to see on x-ray, which made it harder for doctors to place them in precisely the right location.

Realizing that a new approach was needed, scientists at Boston Scientific called their colleagues at NETL in March of 2000 to ask if they could help with research to improve coronary stents. The marriage of energy and medical research may not be glaringly obvious, but Boston Scientific recognized the laboratory’s metallurgical capabilities and offered to fund the entire research project.

Over the next decade, NETL and Boston Scientific worked together to design a new alloy for coronary stents and to develop a process to produce the alloy for use as stent material. The stents that resulted solved many of the problems of traditional stents. The addition of platinum allowed stents made from the new alloy to be both thin and visible on x-ray. Their flexibility allowed easier movement through arterial bends without causing damage. The stents have higher corrosion resistance, which optimizes the stent’s long-term stability within the body, and their increased strength decreases recoil, which reduces the chances of constriction after deployment.

Following a series of trials, Boston Scientific’s PROMUS® ELEMENT™ and ION™ stents, made from the novel alloy, were ready to market.

And a star was born.

Since their introduction in 2010, coronary stents made from the new alloy have generated more than $4 billion in worldwide sales, and captured 45 percent of the U.S. coronary stent market and 33 percent of the global market, generating 450 high-paying, sustainable American jobs. And in late 2012, Boston Scientific received approval for platinum-chromium stents to be used in the treatment of peripheral artery disease, particularly in the legs, where the stents have dramatically reduced the risk of death and limb amputation for patients with this disease.

The take-home message is that good things come in small packages and that the research done by DOE labs like NETL can have far-reaching benefits.