-- This project is inactive --

Terrafore, under the Baseload CSP FOA, developed novel encapsulated phase change materials (PCM) for use in thermal storage applications to significantly reduce the levelized cost of energy (LCOE) for baseload CSP plants.

Approach

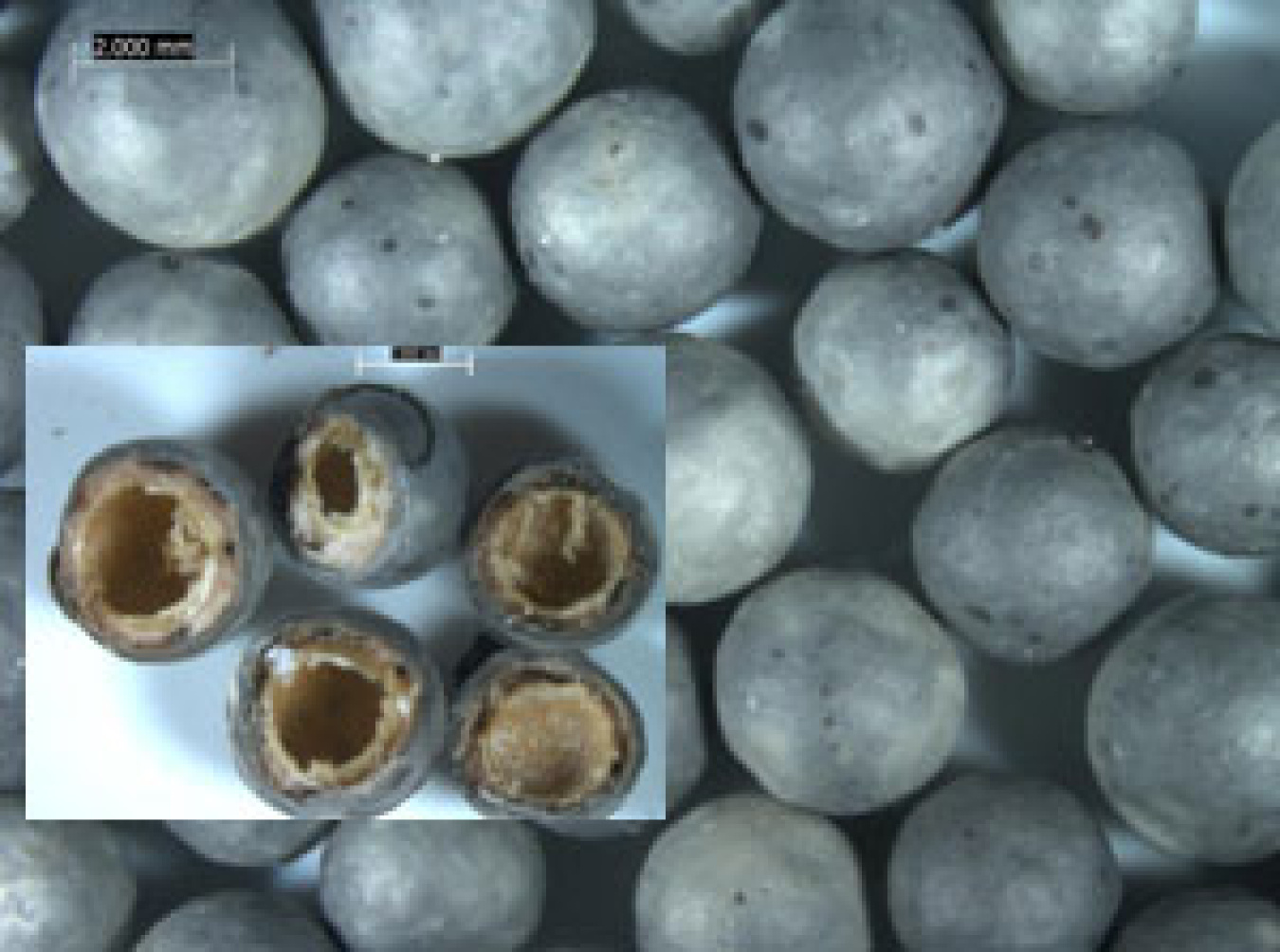

Terrafore worked to determine a cost-effective way to produce small 10 mm to 15 mm capsules containing phase change material (PCM salt) in a suitable shell material. Large numbers of these PCM capsules provide high-heat transfer surface and store heat as sensible and latent heat of fusion of salt. The capsules with different PCMs inside the shell are stacked inside a single tank to provide a cascaded storage to effectively use the latent heat of fusion of salts over the solar collection temperature range.

10 to 15 millimeter capsules provide high heat transfer surface.

Innovation

In addition to taking a new approach to PCM encapsulation methods, Terrafore also:

- Designed a single, packed-bed tank system to add and extract heat from the salt in the encapsulated beads by direct contact between a suitable heat transfer fluid (HTF) and the beads

- Designed a controller to actively maintain thermal stratification by using predictive control strategies.

The technical objective of this project was to determine how to prevent the rupturing of the encapsulating shell, or capsule, when the core PCM melts and the volume increases.

Conclusion

By encapsulating PCM in small capsules using a patented “sacrificial-layer” method, Terrafore successfully demonstrated and optimized the manufacturing of capsules containing phase-changing inorganic salts. By using these capsules, Terrafore increased the heat transfer area per unit volume of salt and brought the heat transfer fluid in direct contact with the capsules. These two improvements have increased the heat transfer coefficient and boosted heat transfer.

The program was successful in overcoming the phenomenon of melt expansion in the capsules, which requires the creation of open volume in the capsules or shell to allow for expansion of the molten salt on melting and is heated above its melting point to 550°C. The research team demonstrated the process with a commonly used inorganic nitrate salt in a low-cost shell material that can withstand over 5,000 high-temperature thermal cycles between 250°C and 450°C. The shell used to encapsulate the salt was demonstrated to be compatible with a nitrate based molten salt heat transfer fluid typically used in CSP plants to temperatures up to 600 °C and withstood over 5000 thermal cycles between 250°C and 450°C.

Final Report

Mathur, Anoop. Using Encapsulated Phase Change Material in Thermal Energy Storage for Baseload Concentrating Solar Power (EPCM-TES). No DE-EE0003589. 2013. doi:10.2172/1184415

Publications, Patents, and Awards

- Mathur, Anoop Kumar, and Rajan Babu Kasetty. "Thermal energy storage system comprising encapsulated phase change material." U.S. Patent Application No. 13/187,398.

Learn about other concentrating solar power research.