Steam sterilizers are heated by steam that condenses and flows to the trap drain beneath the sterilizer.

The Federal Energy Management Program (FEMP) identified steam sterilizer condensate retrofit kits as a water-saving technology that is relevant to the federal sector, is commercially available, and offers significant water-savings potential.

This overview provides agencies with key information to deploy innovative products and systems that may otherwise be overlooked. It also helps agencies identify water-efficient technologies for consideration when entering into energy savings performance contracts or utility energy service contracts.

FEMP used the following considerations when selecting this technology.

- Underutilized in the federal sector

- Broad applicability across the federal sector

- Water and cost savings potential

- Market availability

- Produced by multiple manufacturers

- Ease of installation/suitable as a retrofit

Technology Description

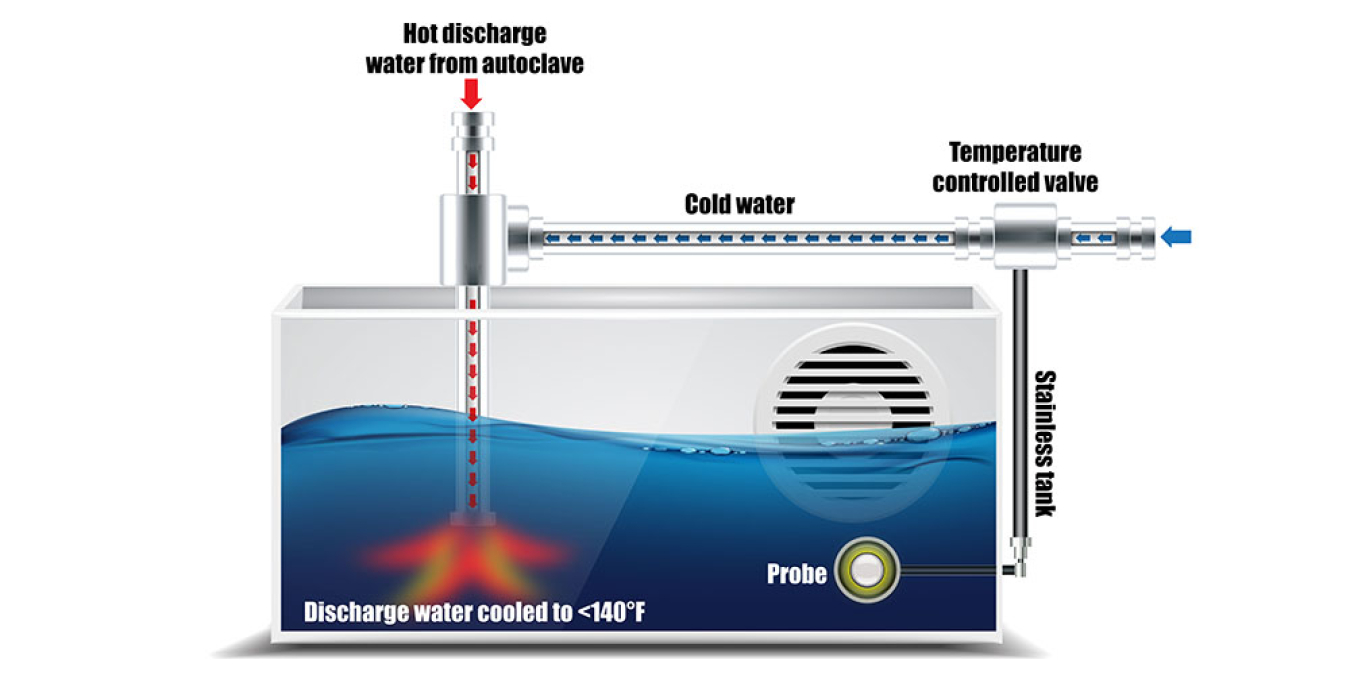

Steam sterilizers disinfect equipment commonly found in hospitals, clinics, and laboratories. Steam sterilizer operation consists of either ready/standby mode or active sterilization mode. In ready/standby mode, the sterilizers are continuously heated by steam that condenses and flows to the trap drain beneath the sterilizer. Sterilizers operate in ready/standby mode most of the time. Plumbing code requirements prohibit sewer discharge temperatures from exceeding 140°F, so the condensed steam from the sterilizer must be cooled before being discharged into a building’s sewer piping. This is typically done using a continuous flow of cool tap water.

To eliminate the need for a continuous flow of water, a jacket and chamber condensate kit can be installed on the sterilizer. The retrofit kit consists of a small, uninsulated tank that captures the condensate during ready/standby mode and dissipates heat to the room before discharging the cooled condensate. If temperatures exceed 140°F, a thermostatically controlled valve allows cool tap water to enter the chamber, so code requirements are not violated. Retrofitting a steam sterilizer with a kit reduces the amount of water needed to cool the condensed steam during the ready/standby operation, significantly reducing in overall water use.

Technology Considerations

Multiple manufacturers produce jacket and chamber condensate retrofit kits. These kits are aftermarket modifications designed for large, freestanding sterilizers rather than the smaller tabletop units, which generally use little water during operation. The unit is small enough to fit beneath most freestanding sterilizers, so space constraints are not an issue.

Proven Savings Potential

Typical sterilizers continuously use between 1 gallon and 5 gallons per minute to reduce the temperature of the hot condensate used in the sterilization process before it is sent down the drain. This retrofit eliminates the flow of tempering water during ready/standby mode of the operating cycle. Jacket and chamber condensate retrofits have been reported to reduce the tempering water consumed by sterilizers by 90%. (Source: Fitch, et al., Steam Sterilizers at Stanford University. Environmental Quality and Water Efficiency Group, Stanford University.)

More Opportunities

Read about additional water-efficient technology opportunities: