Federal agencies may have water uses that can be met with alternative water sources. Alternative waters are sustainable sources of water, not supplied from fresh surface water or groundwater, that offset the demand for freshwater. Alternative water can serve as a vital water supply to federal agencies in support of water resilience by providing diverse water sources.

Examples of alternative water sources include:

- Harvested rainwater from roofs

- Harvested stormwater

- Reclaimed wastewater

- Graywater

- Captured condensate

- Additional alternative water sources

- Atmospheric water generation

- Discharged water from water purification processes

- Foundation water

- Blowdown water

- Desalinated water.

This best management practice (BMP) provides an overview of these alternative water sources.

Implementing alternative water projects requires careful planning to ensure that the right water sources are collected for the most appropriate uses. There are several criteria to consider when making these selections:

- Choose Sites with Adequate Alternative Resources and High Water Uses: Choose locations with high potential for the alternative supply (e.g., adequate rainfall for harvesting rainwater/stormwater) and high water demand for the applications that can use the alternative source (e.g., golf course irrigation). Investigate potential sources of alternative water using the Federal Energy Management Program's (FEMP) alternative water maps.

- Consider Water Security as a Main Driver: Select sites with high water risk and critical functions so alternative water systems can help to reduce water risk and provide a redundant water supply to applications that are necessary to minimize interruption of the facility function. For example, alternative water can provide toilet flushing and cooling tower make-up water to critical buildings that must be operable during a water disruption.

- Select Sites Where Alternative Water Can Be Used in Multiple Applications: Alternative water systems are most effective if they can supply multiple end uses, such as vehicle wash, landscape irrigation, and dust suppression.

- Size the System Based on Water Demand: When sizing a system, it is important to accurately estimate the site's water demand by the application type and to size the storage requirements based on the amount of water needed for that application.

- Design the Proper Water Treatment for the Application: Carefully consider the desired water quality for the supply and the application types when determining the treatment requirements. Alternative water can be treated to non-potable or potable standards depending on need.

- Plan Early for Required Permitting: Alternative water systems may require local or state permits. Work closely with the local permitting office early to give ample time to complete this process.

- Implement An Operation and Maintenance (O&M) Program: Having trained, onsite personnel or a maintenance contract in place to perform ongoing O&M is critical to making sure these systems continue to operate as designed.

The remainder of this BMP describes alternative water sources and considerations to account for when planning for implementation.

Rainwater harvesting is the collection of rainwater from rooftops or other covered surfaces to divert and store for later use. Harvested rainwater is commonly used for non-potable applications, often to irrigate landscaping. Other common uses include wash applications, cooling tower make-up, and dust suppression.

Harvesting rainwater can provide stormwater management by decreasing the amount of runoff flow and in turn runoff velocity, which reduces flooding and erosion since slower runoff soaks into the ground and reduced runoff avoids soil saturation—an option to turn stormwater problems into water supply assets. Less runoff also means less contamination of surface water from sediment, fertilizers, pesticides, and other pollutants potentially transported in rainfall runoff.

The level of treatment required for harvested rainwater depends on how the water will be used. Minimal treatment is required for irrigation because rainwater is typically free of salts and other harmful minerals. More treatment may be required for other non-potable applications such as cooling tower make-up and toilet flushing. Rainwater can be further treated to potable standards and used throughout a building for all end uses. However, the system will require comprehensive treatment and disinfection to meet safe drinking water standards.

In a typical potable harvested rainwater system, a strainer basket separates debris from the collection system. Water is disinfected at regular intervals with ozone by an ozone generator or ultraviolet light systems. Pumps push water through filter cartridges to break tanks, where chlorine or similar chemical treatments are injected as a final step in the treatment process before the water is returned to the building or sent to another end use.

Maps and Tools

Rainwater harvesting is not regulated by the federal government. Individual states regulate the collection and use of rainwater. FEMP's interactive Rainwater Harvesting Tool visually represents the state-level rainwater harvesting regulations across the U.S. and offers general information about the applicable state programs. This map can be used to quickly discern where rainwater harvesting is supported and regulated by the state.

The Rainwater Harvesting Tool also depicts the range of rainwater available for harvesting for year-round applications and landscape irrigation across the U.S. FEMP also developed the Rainwater Harvesting Calculator, which estimates the amount of monthly rainfall that can be harvested.

Implementation Considerations

- Rainwater collection and distribution systems can be incorporated into almost any site, although it is easier and most efficient to incorporate them into new construction.

- Rainwater harvesting systems may require a permit from local or state government. Plan for this requirement early.

- Rainwater harvesting systems require regular O&M. FEMP developed an overview that provides key information to deploy rainwater harvesting systems along with O&M requirements.

- Make sure the tank and equipment location will not obstruct daily operations.

- Properly size the tank to optimize the amount of rainfall collected.

- A first flush diverter should be included in the system components to help reduce the amount of debris that enters the system.

- System specifications should include components and considerations to prevent mosquitos from breeding in and around the system, such as ensuring proper drainage to prevent pooling water.

- Install high-quality industrial-grade components.

- Configure the roof and gutters to harvest as much rain as possible and try to select roofs without overhanging vegetation that may prevent rainfall from hitting the roof or produce debris that may clog the gutter system.

- Equipment should be in a secure location to reduce tampering. Also, system components should be enclosed to protect equipment from the environment (e.g., weather, animals).

Stormwater is precipitation runoff over ground-level surfaces that has not infiltrated into the ground and has not entered a waterway such as a stream or lake. Stormwater is typically treated to non-potable levels when used in non-potable applications. Common uses of harvested stormwater include irrigation, wash applications, cooling tower make-up or process water, and dust suppression, among others.

Harvesting stormwater differs from harvesting rainwater in that runoff is collected from ground-level hard surfaces rather than from roofs. Benefits of stormwater harvesting include reduction of pollutants and potential flooding from large water events that flow to surface water. Other benefits include reduction of stream bank erosion, sewer overflows, and infrastructure damage.

Stormwater is generally collected onsite from hard surfaces such as sidewalks, streets, and parking lots before it enters a waterway. After being diverted, it is stored temporarily in retention ponds or tanks. The characteristics of stormwater harvesting and reuse systems vary considerably by project, but most systems include collection, storage, treatment, and distribution.

Captured stormwater normally requires more treatment than captured rainwater because it is exposed to additional pollutants from drainage systems and surfaces that may have hydrocarbons or other miscellaneous debris. Treatment options to reduce pathogens and pollution levels include the use of constructed wetlands, sand filters and membrane filters, and disinfection techniques including chlorination and ultraviolet radiation. The degree of treatment required depends on the proposed use and the level of public exposure.

Stormwater that is diverted for reuse may impact the amount of water available for other consumers downstream from the diversion point. Water utilities and municipalities may charge augmentation fees to recover costs associated with augmenting water to the watershed to maintain enough supply for downstream customers.

Implementation Considerations

- Successful stormwater harvesting projects need expert input from several areas, including stormwater management, water supply management, environmental management, and public health.

- There may be local limitations on the storage and reuse of stormwater and/or there may be permit requirements from local or state governments. Plan early for these types of requirements.

- Stormwater availability and application water demand need to be considered when designing the system; is stormwater available seasonally, intermittent, or year-round?

- There may be site constraints in constructing the infrastructure needed to harvest stormwater.

- Stormwater systems require routine maintenance. Make sure to institute a comprehensive O&M program that includes:

- Monitoring of storage

- Monitoring for leaks

- Maintaining treatment systems, including filter replacement and disinfection equipment maintenance

- Testing water quality

Reclaimed wastewater is water that is discharged from buildings and processes, treated at a wastewater treatment facility, and then reused in applications such as irrigation and industrial processes. Federal sites that treat wastewater onsite can potentially reclaim wastewater, and it is becoming more common for local municipalities to reclaim wastewater and sell it to customers to help lower the community's demand for freshwater. This water can sometimes be available at a lower cost than otherwise purchased potable water. FEMP provides an interactive map showing water utilities that supply reclaimed wastewater to their customers.

Reclaimed wastewater is typically treated to non-potable levels and used in non-potable applications such as irrigation and cooling tower make-up. This water is distributed through a separate distribution system, commonly referred to as "purple pipe" (denoting the color of the pipes). Non-potable reclaimed wastewater typically requires secondary treatment such as additional filtration and disinfection to further remove contaminants and particulates to ensure the water is safe for non-potable applications.

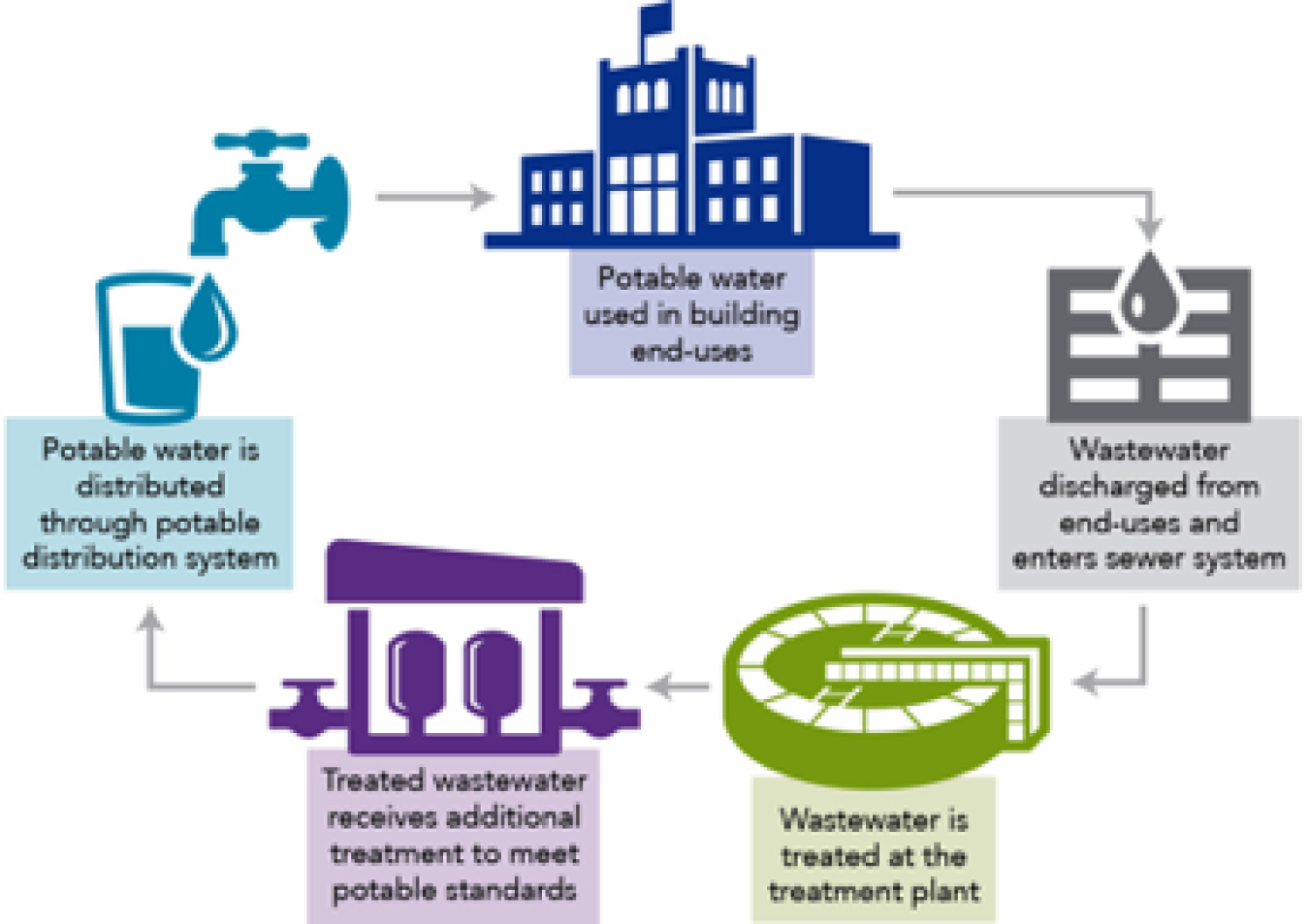

Although uncommon, reclaimed wastewater can also be treated to potable standards. There are two general types of potable reclaimed wastewater systems:

- Direct potable reuse (DPR)

- Indirect potable reuse (IPR).

DPR introduces treated reclaimed wastewater directly into a potable water treatment plant and then through the potable distribution system. Figure 1 is a schematic of DPR phases. IPR introduces reclaimed wastewater into a natural watershed (e.g., groundwater aquifer or reservoir) acting as an environmental buffer, where water can subsequently be withdrawn and treated to potable standards.

An efficient and successful reclaimed water project requires a reliable source of wastewater of adequate quantity and quality to meet the water needs. These projects may be more economically viable when the cost of freshwater is high and there is a lack of high-quality freshwater or there are future supply risks due to conditions such as drought.

Implementation Considerations

- State and local governments regulate the use of reclaimed wastewater and the associated water quality requirements. Plan early for this requirement.

- To minimize cross-connection problems, non-potable reclaimed water pipes must be color coded with purple tags or tape according to standards set by the American Water Works Association.

- Signs should be used to indicate that reclaimed water is non-potable. Place these signs in public places such as in front of a fountain and on valves, meters, and fixtures.

- To avoid accidental cross-connection, keep the pressure of reclaimed water 10 psi lower than potable water mains to prevent backflow.

- Run reclaimed water mains at least 12 inches lower in elevation than potable water mains and horizontally at least five feet away.

- Review the quality of reclaimed water to minimize the potential for harmful effects from long-term use, such as salt buildup.

- See the following for consideration for a potable system:

Graywater is lightly contaminated water that is generated by bathroom sinks, showers, and clothes washing machines. Graywater does not include wastewater from toilets, urinals, or kitchens. Graywater is typically used in non-potable applications, most commonly to flush toilets and urinals, irrigate landscape, and supply water for ornamental ponds and make-up water in cooling towers. Graywater use offers several benefits as it can reduce water withdrawn from freshwater sources, energy and chemicals used to treat water to potable standards, and the volume of wastewater being sent to wastewater treatment facilities.

A graywater reuse system diverts water that normally is discharged to a municipal sewage treatment to use within the same building. Graywater effluent is collected, treated, and distributed for reuse, usually within the same building, and requires retrofitting the plumbing system for existing buildings. Graywater will often contain detergents, dissolved and suspended solids, and pathogens. Basic graywater treatment consists of removing suspended solids from the water, while sophisticated treatment may consist of biological treatment with membrane filtration, activated carbon, and ultraviolet light or ozone disinfection to destroy pathogens. Sophisticated treatment may be required if used in public locations and depending on the source of the water. Water for outdoor (subsurface irrigation) uses may be less treated than water for indoor uses.

The major components of a graywater reuse system include:

- Plumbing that collects graywater from sinks, showers, and laundry

- Water storage tanks, which should be closed to minimize contact

- A treatment system to filter and disinfect water if required; regulations can vary by state and local ordinances

- Secondary plumbing (called dual plumbing) that supplies applications with graywater such as irrigation or toilet flushing that is color-coded to identify piping as a graywater source

- Pumps to transport the water.

Implementation Considerations

- Graywater systems should also be installed in accordance with local plumbing codes and by professional, licensed plumbing contractors. Local requirements may include:

- System inspection after installation to verify compliance

- Extensive labeling, different piping material, and biodegradable dye to distinguish from the building’s potable system

- Backflow preventers to ensure the proper separation of potable water and graywater supply system.

- The use of graywater reuse systems should be considered when constructing new buildings because the dual plumbing system can be integrated into the design with less labor than if retrofitted.

- Prevent pathogenic organisms from contacting humans or animals by treating the water to eliminate pathogens or isolating sanitary graywater from any potable water source. Collecting or storing the graywater in sealed containers can limit human exposure.

- To prevent contamination, sanitary graywater used for irrigation should not be applied through a spraying device, but rather injected directly into the soil through drip irrigation. Rain or excessive irrigating could cause ground saturation and result in pools of graywater on the surface. To help eliminate this situation, turn the graywater system off and divert the graywater to the sanitary sewer line during rainy periods.

- When intending to use graywater for irrigation, consider using biodegradable cleaning products that do not contain sodium, chlorine, or boron when cleaning plumbing fixtures. Cleaning products that contain high chemical levels may enter the graywater recycling system and may require additional treatment so as not to poison plants or damage soil through the buildup of inorganic salts.

- A regular maintenance programs for a graywater system should include the following steps:

- Inspecting the system for leaks and blockages

- Cleaning and replacing the filter

- Replacing the disinfectant

- Ensuring that controls operate properly

- Periodically flushing the entire system.

Additional sources of alternative water that should be considered to offset the use of freshwater include captured condensate, atmospheric water generation, discharge water from water purification systems, foundation (sump) water, blowdown water, and desalinated water.

Captured Condensate

Water condenses on the cooling coils of mechanical equipment such as packaged or rooftop units, dedicated outdoor air units, and air handling units when humid air contacts these cool surfaces. A large amount of condensate can form on cooling coils in areas with hot, humid summers such as the southeastern United States. Water that collects on the cooling coils must be drained to prevent damage to the equipment or building from water buildup. Typically, the condensate is collected in a central location and discharged to a sewer drain. In a condensate capturing system, the condensate is directed to a central storage tank or basin and then distributed for reuse.

Make-up water for cooling towers can be an ideal use of captured air handler condensate. Cooling tower make-up water is needed the most during the hot summer months, when the largest amount of air handler condensate can be collected. Originating from the air, condensate water starts off very pure with a very low dissolved mineral content, ideal for cooling towers; however, condensate can potentially grow bacteria during the storage phase, requiring disinfection to avoid introducing bacteria-contaminated water to the cooling tower system. Condensate can also acquire heavy metals because of contact with cooling coils, and treatment to remove these heavy metals may be required. To limit this contamination, while cleaning the cooling coils, make sure cleaning water does not enter the condensate capture system.

FEMP provides a map depicting the potential for condensate capture from air-conditioning systems across the U.S. It shows an estimate of how much water can be collected and provides an initial assessment of the feasibility of implementing condensate capture from air-conditioning systems at a given location. Read about a federal case study on a condensate capture project implemented by the U.S. Environmental Protection Agency (EPA).

Atmospheric Water Generation

Atmospheric water generation (AWG), also called "air water harvesting," is where a device is used to extract water vapor directly from the air, in the form of humidity, by using condensation of cooling surfaces (as explained in the captured condensate section), desiccant capture, or gas separation using membrane technologies. Water is extracted from air via condensation or pressurization. As air passes over cooled coils or the pressure is increased, the moisture content changes from vapor to liquid, it "condenses," which is then possible to capture and store for later use.

Temperature and humidity of a location will affect how much water can be extracted from the air. Other considerations include the costs and energy requirements of the systems. Colder, humid environments require more energy than warmer, humid conditions.

Make-up water for cooling towers can be an ideal use of AWG, similar to captured condensate. By nature, water originating from AWG is very pure with very low dissolved mineral content, which is ideal for cooling towers except that stored water can potentially grow bacteria during the storage phase, requiring disinfection to avoid introducing bacteria-contaminated water to the cooling tower system. AWG can be used in other non-potable applications, depending on how much water can be collected. With the proper air filtration and water disinfection, AWG can produce potable water.

Water Purification System Discharge Water

Water purification systems, such as reverse osmosis, remove impurities from a water supply for processes that require ultra-pure water. Some of the water supplied to the system is purified, while the remaining water, containing the filtered impurities, is rejected from the system. The ratio of purified water to the total supply water is called the recovery rate. A common recovery rate of a water purification system is between 50% and 75% (source: EPA WaterSense at Work). This equates to 25% to 50% of the total water supplied being rejected, which can be a significant amount of water discharged from the system. Discharge water, or reject water, from these systems can be recovered and reused for non-potable applications.

The discharge water will likely be high in dissolved solids since this is the end product of the water purification system. Therefore, it is important to choose applications where elevated dissolved solids will not cause harm or are properly managed. Appropriate uses of discharge water are toilet and urinal flushing, cooling tower make-up water, irrigation, and vehicle wash. For cooling tower make-up, the total dissolved solids (TDS) of the discharge water should be less than the TDS set point of the cooling tower. If discharge water is used for landscape irrigation, the landscape plants should have a high tolerance for salinity. Read about reverse osmosis optimization.

Foundation Water

Buildings may have issues with water that collects around the foundation and basement/crawlspaces from groundwater or drainage from stormwater runoff. This alternative water type is also referred to as “sump pump" water because the foundation water is typically pumped away from the foundation using a sump-pump to prevent flooding. This water normally goes directly into a storm or sewer system; however, it can be recovered and reused similar to harvested stormwater. Applications for this water include toilet and urinal flushing, cooling tower make-up water, irrigation, and vehicle wash.

Blowdown Water

Blowdown water is water that is drained from cooling equipment and boilers to remove mineral buildup that develops during water evaporation cooling or steam production. As water evaporates, the concentration of minerals increases, necessitating removal of minerals from the system. Systems that may require blowdown include cooling towers, evaporative condensers, evaporative coolers, evaporative cooled air-conditioners, and central boilers. Blowdown water normally is discharged directly into the sewer system; however, it can be recovered and reused for other applications.

Blowdown water may be used for irrigation, but there are some considerations to keep in mind. Blowdown water may have high levels of minerals that may not be appropriate for irrigation or could be diluted with another source of water before being used for irrigation. Plant species that prefer acidic soils (e.g., pine trees) should not be watered with blowdown water. Other applications of blowdown water can be considered, but the high mineral content of the water may damage equipment by causing mineral buildup, so it might be necessary to dilute the water with another source.

Desalinated Water

Desalinated water is brackish water or seawater from which the dissolved minerals, salts, and other contaminants have been removed. Most desalination processes use either multistage flash or reverse osmosis to remove the salts from the water. The multistage flash method rapidly boils the brackish/seawater multiple times to collect the freshwater and remove the salts. Reverse osmosis works by moving the brackish/seawater at high pressure across a semi-permeable membrane that the salts cannot pass through.

The desalination process typically is designed to produce potable water, which can be used for drinking water or other applications that need high water quality (e.g., steam boilers). Desalination is costly because it consumes a large amount of energy and requires significant maintenance. In addition, the process produces a brine that requires proper disposal, specifically a concentrated salt by-product.