When light shines on a photovoltaic (PV) cell – also called a solar cell – that light may be reflected, absorbed, or pass right through the cell. The PV cell is composed of semiconductor material; the “semi” means that it can conduct electricity better than an insulator but not as well as a good conductor like a metal. There are several different semiconductor materials used in PV cells.

When the semiconductor is exposed to light, it absorbs the light’s energy and transfers it to negatively charged particles in the material called electrons. This extra energy allows the electrons to flow through the material as an electrical current. This current is extracted through conductive metal contacts – the grid-like lines on a solar cells – and can then be used to power your home and the rest of the electric grid.

The efficiency of a PV cell is simply the amount of electrical power coming out of the cell compared to the energy from the light shining on it, which indicates how effective the cell is at converting energy from one form to the other. The amount of electricity produced from PV cells depends on the characteristics (such as intensity and wavelengths) of the light available and multiple performance attributes of the cell.

An important property of PV semiconductors is the bandgap, which indicates what wavelengths of light the material can absorb and convert to electrical energy. If the semiconductor’s bandgap matches the wavelengths of light shining on the PV cell, then that cell can efficiently make use of all the available energy.

Learn more below about the most commonly-used semiconductor materials for PV cells.

Silicon

Silicon is, by far, the most common semiconductor material used in solar cells, representing approximately 95% of the modules sold today. It is also the second most abundant material on Earth (after oxygen) and the most common semiconductor used in computer chips. Crystalline silicon cells are made of silicon atoms connected to one another to form a crystal lattice. This lattice provides an organized structure that makes conversion of light into electricity more efficient.

Solar cells made out of silicon currently provide a combination of high efficiency, low cost, and long lifetime. Modules are expected to last for 25 years or more, still producing more than 80% of their original power after this time.

Thin-Film Photovoltaics

A thin-film solar cell is made by depositing one or more thin layers of PV material on a supporting material such as glass, plastic, or metal. There are two main types of thin-film PV semiconductors on the market today: cadmium telluride (CdTe) and copper indium gallium diselenide (CIGS). Both materials can be deposited directly onto either the front or back of the module surface.

CdTe is the second-most common PV material after silicon, and CdTe cells can be made using low-cost manufacturing processes. While this makes them a cost-effective alternative, their efficiencies still aren't quite as high as silicon. CIGS cells have optimal properties for a PV material and high efficiencies in the lab, but the complexity involved in combining four elements makes the transition from lab to manufacturing more challenging. Both CdTe and CIGS require more protection than silicon to enable long-lasting operation outdoors.

Perovskite Photovoltaics

Perovskite solar cells are a type of thin-film cell and are named after their characteristic crystal structure. Perovskite cells are built with layers of materials that are printed, coated, or vacuum-deposited onto an underlying support layer, known as the substrate. They are typically easy to assemble and can reach efficiencies similar to crystalline silicon. In the lab, perovskite solar cell efficiencies have improved faster than any other PV material, from 3% in 2009 to over 25% in 2020. To be commercially viable, perovskite PV cells have to become stable enough to survive 20 years outdoors, so researchers are working on making them more durable and developing large-scale, low-cost manufacturing techniques.

Organic Photovoltaics

Organic PV, or OPV, cells are composed of carbon-rich (organic) compounds and can be tailored to enhance a specific function of the PV cell, such as bandgap, transparency, or color. OPV cells are currently only about half as efficient as crystalline silicon cells and have shorter operating lifetimes, but could be less expensive to manufacture in high volumes. They can also be applied to a variety of supporting materials, such as flexible plastic, making OPV able to serve a wide variety of uses.PV

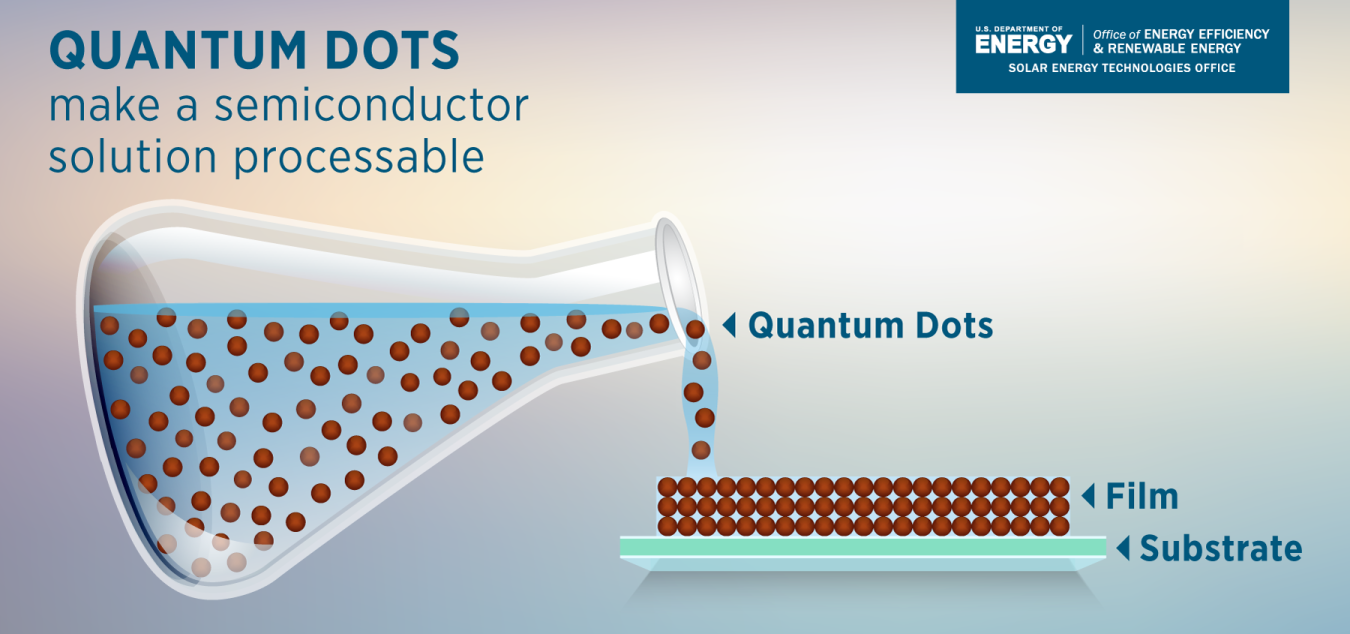

Quantum Dots

Quantum dot solar cells conduct electricity through tiny particles of different semiconductor materials just a few nanometers wide, called quantum dots. Quantum dots provide a new way to process semiconductor materials, but it is difficult to create an electrical connection between them, so they’re currently not very efficient. However, they are easy to make into solar cells. They can be deposited onto a substrate using a spin-coat method, a spray, or roll-to-roll printers like the ones used to print newspapers.

Quantum dots come in various sizes and their bandgap is customizable, enabling them to collect light that’s difficult to capture and to be paired with other semiconductors, like perovskites, to optimize the performance of a multijunction solar cell (more on those below).

Multijunction Photovoltaics

Another strategy to improve PV cell efficiency is layering multiple semiconductors to make multijunction solar cells. These cells are essentially stacks of different semiconductor materials, as opposed to single-junction cells, which have only one semiconductor. Each layer has a different bandgap, so they each absorb a different part of the solar spectrum, making greater use of sunlight than single-junction cells. Multijunction solar cells can reach record efficiency levels because the light that doesn’t get absorbed by the first semiconductor layer is captured by a layer beneath it.

While all solar cells with more than one bandgap are multijunction solar cells, a solar cell with exactly two bandgaps is called a tandem solar cell. Multijunction solar cells that combine semiconductors from columns III and V in the periodic table are called multijunction III-V solar cells.

Multijunction solar cells have demonstrated efficiencies higher than 45%, but they’re costly and difficult to manufacture, so they’re reserved for space exploration. The military is using III-V solar cells in drones, and researchers are exploring other uses for them where high efficiency is key.

Concentration Photovoltaics

Concentration PV, also known as CPV, focuses sunlight onto a solar cell by using a mirror or lens. By focusing sunlight onto a small area, less PV material is required. PV materials become more efficient as the light becomes more concentrated, so the highest overall efficiencies are obtained with CPV cells and modules. However, more expensive materials, manufacturing techniques, and ability to track the movement of the sun are required, so demonstrating the necessary cost advantage over today's high-volume silicon modules has become challenging.

Learn more about photovoltaics research in the Solar Energy Technologies Office, check out these solar energy information resources, and find out more about how solar works.